The International Energy Agency’s latest annual gas market report, Gas 2018, estimated that global gas demand could reach more than 4,100 billion cubic meters (bcm) in 2023. This is an increase from 3,740 bcm in 2017. Greater gas demands mean more oil rigs, and the machines on these rigs break down.

AI could help oil and gas companies predict when their machines and equipment require maintenance. Oil and gas companies can then repair these machines before their breakdowns result in long downtimes or employee injuries that could cost millions in legal fees and settlements.

The companies in this report all claim to help oil and gas, energy, and utility companies with at least one of the following:

- Monitoring their machine assets

- Predicting the probability of future machine failures

- Making proactive maintenance decisions

- And as a result, reducing operational costs arising from catastrophic machine failures

We begin our analysis of how energy companies can use AI to predict when their machines will break down with Uptake Technologies.

Uptake Technologies

Uptake Technologies offers its Asset Performance Management (APM) application, which it claims can help oil and gas companies monitor their machine assets, predict future machine failures, and make proactive maintenance decisions using machine learning.

Uptake claims that the APM is driven by the Asset Strategy Library (ASL), a dataset containing data about machinery and equipment types, their failure mechanisms, as well as fluids and inspection data, fault codes, and operating thresholds.

The company states the machine learning model behind the software was trained on more than 800 asset types used in the energy, chemical, manufacturing, and mining industries, 10 million components, and the 58,000 ways they can fail.

The application can be applied on the edge and in the cloud. The company states that oil and gas experts at the client company would need to determine where to install sensors on the cylinder.

These sensors would then collect telemetric data from those parts of the cylinder, such as pressure. This data would then be used as a baseline for a properly functioning cylinder.

The machine learning model behind the software would need to be trained on millions of these telemetric data points and data about when certain parts of the cylinder required maintenance, how long maintenance on those parts took, and possibly how long replacement parts took to arrive on site. The data would then be run through the software’s machine learning algorithm.

This would train the algorithm to discern which of all these data points correlate to properly functioning cylinder parts, the time at which the cylinder has needed maintenance in the past, and which of its parts needed repair.

The software would then be able to predict when certain parts of their cylinder are due for maintenance before they break down.

We could not find a demonstration video of this company’s software.

Uptake claims to have helped MidAmerican Energy Company increase its wind turbine availability. Within 48 hours after Uptake was deployed at the wind farm, the application found signs of failure in a main bearing in Tower 17, signs that were similar to previous conditions that lead to a gearbox malfunction.

Uptake alerted the client’s engineering and asset management team. Upon a physical inspection of the tower, the asset management team discovered the issue as predicted by the application.

This early detection allowed the team to fix the wind turbine at a cost of $5,000 and little downtime, saving MidAmerican $250,000 it would have spent if the gearbox had broken down.

MidAmerican also reports that within about three months of using Uptake’s software, the client had generated high-value information from 10% of its turbines.

Uptake Technologies also lists Caterpillar, Blanchard Cat, Ohio Cat, Magnetrol, BHE Renewables, and the US Army as some of its past clients.

Adam McElhinney is Chief of Machine Learning & AI Strategy at Uptake Technologies. He holds an MS in Statistics from the University of Illinois at Chicago. Previously, McElhinney served as Adjunct Faculty of the Department of Mathematics and Computer Science at Illinois Institute of Technology and as Board Member of the College of Engineering Advisory Board, the University of Illinois.

C3.ai

C3.ai offers a preventive maintenance application which it claims can help oil and gas, aerospace and defense, financial services, healthcare, manufacturing, and other companies prioritize equipment maintenance, maximize uptime, improve the safety and security of workers, and reduce expenses using predictive analytics.

C3 claims that clients can integrate the software into enterprise databases, adding that the machine learning model behind the software was trained on historical failure data.

The user could then upload sensor data, supervisory control, and data acquisition (SCADA) data, legacy data, plus data such as technician notes, and external data sources such as weather that are not labeled into its software.

The algorithm behind the software would then be able to detect anomalies in the assets and computes the failure risk score of each asset by analyzing operating conditions and asset performance data. The system provides an estimate of the probability of failure over different periods, such as 14 days, 30 days, or six months.

The company states oil and gas experts at the client company would need to determine where to install sensors on the beam pump, for instance. These sensors would then collect telemetric data from those parts of the beam pump, such as rounds per minute or applied force. This data would then be used as a baseline for a properly functioning beam pump.

The machine learning model behind the software would need to be trained on millions of these telemetric data points and data about when certain parts of the beam pump required maintenance, how long maintenance on those parts took, and possibly how long replacement parts took to arrive on site. The data would then be run through the software’s machine learning algorithm.

This would train the algorithm to discern which of all these data points correlate to properly functioning beam pump parts, the time at which the beam pump has needed maintenance in the past, and which of its parts needed repair.

The software would then be able to predict when certain parts of their [beam pump] are due for maintenance before they break down.

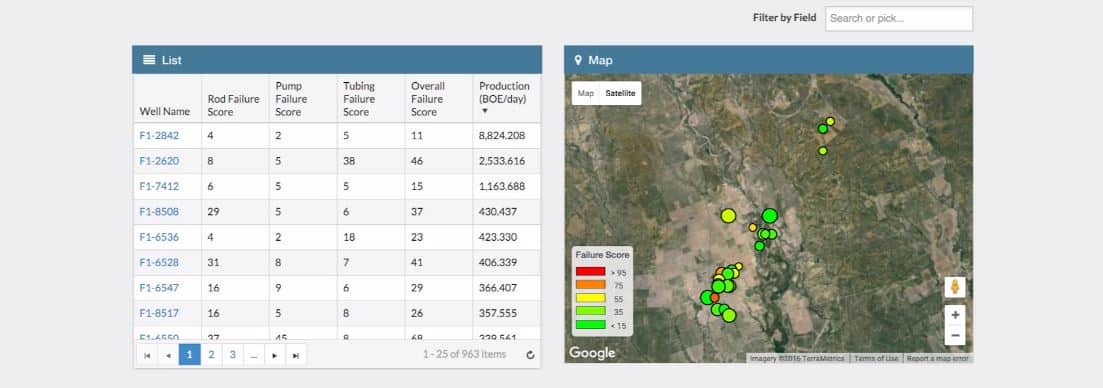

Below is a short 4-minute video demonstrating how the C3 software offers a manager-level overview of the dashboard. The video explains that the application displays failure risk scoring of oil wells with lowest and highest risk of failure. The geospatial visualization gives users a view of the location of the oil wells, color-coded for easier distinction. The dashboard also displays the historical data of the wells’ failures and failure type.

C3 claims to have helped Enel in 2013 to deploy an enterprise-wide digitalization, part of which included fraud detection and predictive maintenance software.

Enel also deployed the C3 Predictive Maintenance application for five control centers to improve power grid reliability to meet capacity and demand, and reduce anomalies in the electric current called faults.

The application was set up to collect and analyze network sensor data, smart meter data, asset maintenance records, and weather data to predict failure of the feeder line which is a power line that transfers power from a distribution substation to the distribution transformers. The application integration took three months, while testing took another three months.

The case study reported that the project used 25 data sources and monitored 50 million sensors. Enel estimated a potential $7.57 billion in combined savings and revenue once the digitalization is fully implemented after a five-year period which ended in 2018.

C3 also lists Engie, Eversource, Con Edison, SDGE, and BGE as some of its past clients. The company has raised $228.5 million in funding from The Rise Fund, Sutter Hill Ventures, Breyer Capital, TPG Growth, Thomas Siebel, Wildcat Venture Partners, and Pat House.

Ed Abbo has been the President and CTO at C3 since 2011. He holds an MS in Mechanical Engineering from MIT. Previously, Abbo served as Vice President for Applications at Oracle for 15 years.

MapR Technologies

MapR Technologies offers a Predictive Maintenance application, which it claims can help oil and gas companies improve efficiency and cut operational costs through better asset tracking and predictive maintenance using machine learning.

MapR claims businesses can integrate the the MapR Data Platform into their on-premises, cloud, and edge data collection and storage systems.

The company states the machine learning model behind the software was trained on historical data from industrial equipment for oil rigs, chemical plants, or mining operations. The user could then upload image files, sensor data, seismic measurements, and maintenance data that are not labeled into the MapR Converged Data Platform. The company claims that analysts can also use the the MapR Platform to understand how weather affects operations.

The algorithm behind the software would then be able to ingest and analyze current and historical sensor data. The algorithms would then be able to distinguish the patterns between normal and anomalous behavior across the different types of equipment. The system then alerts the asset or operations team of minor malfunctions.

Below is a short 3-minute video explaining how the company’s predictive maintenance software accesses data from the edge, on premises, and the cloud. The system then ingests, stores, manages, analyzes, and applies that data:

MapR claims to have helped National Oilwell Varco (NOV), a designer and manufacturer of oil and gas drilling equipment and parts, create a big data platform that would ingest and store data from sensors and control systems within the organization, to support the deep analytics and machine learning processes.

According to the case study, NOV created a data storage system that can hold 750 billion to 5 trillion data points per terabyte. According to the case study, this will allow NOV to store all sensor data on a single cluster. No other details were provided.

MapR also lists Boehringer Ingelheim, Cisco, Cision, ComScore, Audi, HP, Credit Agricole, Denver Health, and Novartis as some of its past clients.

Ted Dunning has been the Chief Application Architect at MapR Technologies for eight years. He holds a PhD in Computer Science from Sheffield University. Previously, Dunning served as CTO of Deepdyve and Chief Scientist at SiteTuners, Veoh Works, and ID Analytics, among others.

SpaceTime Insight

Spacetime Insight offers its Asset Analytics application, which it claims can help electricity, water, and gas utilities, renewable energy, manufacturing, and transport companies reduce costs and downtime from asset failure using machine learning.

Spacetime Insight, acquired by Nokia in May 2018, claims it can integrate the software into the client company’s maintenance and repair schedules.

The company states the machine learning model behind the software was trained on real or a subset of the complete data set, consisting of information from sensors, devices, and other assets. The user could then analyze the customer’s data such as sensor data, as well as information related to an asset’s age, condition, location, network relationships, and operating history that are not labelled into its software.

The algorithm behind the software would then be able to find clusters of similar items, detecting anomalous data. The system then predicts the probability of asset failure and enable asset managers to make informed decisions about maintenance and repair schedules, or the asset’s remaining useful life.

We can infer oil and gas experts at the client company would need to determine where to install sensors on the pipes and valves. These sensors would then collect telemetric data from those parts of the pipes and valves, such as the pressure and flow. This data would then be used as a baseline for properly functioning pipes and valves.

The machine learning model behind the software would need to be trained on millions of these telemetric data points and data about when certain parts of the pipes and valves required maintenance, how long maintenance on those parts took, and possibly how long replacement parts took to arrive on site. The data would then be run through the software’s machine learning algorithm.

This would train the algorithm to discern which of all these data points correlate to properly functioning pipe and valve parts, the time at which the pipes and valves have needed maintenance in the past, and which of its parts needed repair.

The software would then be able to predict when certain parts of their pipes and valves are due for maintenance before they break down.

Below is a short 3-minute video demonstrating how the company’s software displays assets as color-coded representations to help users identify at-risk assets. The application tracks and displays the relationship between assets, allowing users to understand how one asset can affect the entire system:

SpaceTime Insight does not feature a predictive maintenance case study on its site, but claims to have helped the California Independent System Operator (ISO) implement a situational intelligence system to monitor and manage a crisis. The California ISO integrated Nokia’s Market Intelligence, Grid Intelligence, Renewable Integration and Crisis Intelligence industrial Internet of Things into its control center.

According to the case study, before implementing situational intelligence, California ISO poured over pages of information to discover anomalies. Each team had its own monitoring system and manually coordinated with other teams, making communication prone to misunderstanding and delays.

Nokia’s situational intelligence system today provides current visual displays, allowing teams to correlate and overlay any data needed to understand the potential risk of a situation, such as a natural disaster.

The geospatial displays on the 80 x 6.5-foot video wall at the control center assure operators and dispatchers that everything is running normally or allows them to act on anomalies. The system also enables multiple teams to view the same information and be on the same page when action is required.

SpaceTime Insight also lists E ON, Entergy, Florida Power and Light, American Water, Arizona Public Service, and BC Hydro as some of its past clients.

Paul Hoffman was CTO at SpaceTime Insight prior to the acquisition by Nokia, but recently left the company. It is unclear who takes on the role. Hoffman holds a PhD in Physics from Technische Universität Darmstadt. Previously, he served as CTO at Saffron Technology, which was acquired by Intel.

At the moment, the IoT Analytics applications is under the purview of Bhaskar Gorti, President of Nokia Software. He holds an MSc in Electrical Engineering from Virginia Tech, and served as Senior VP and General Manager at Oracle for nine years.

Header Image Credit: Costain