DHL is a German logistics company that offers parcel delivery, express mail, freight forwarding, and third-party logistics. Its parent company is Deutsche Post (‘DPDHL’), the world’s largest logistics enterprise, operating in over 220 countries and employing more than 510,000 people worldwide.

All company financials are provided by DPDHL. In its 2021 annual report, DPDHL reported a pre-tax profit (EBIT) of approximately $8 billion on almost $82 billion in revenue. Deutsche Post has a market capitalization of $52.18 billion Euro (≅$53.16 billion USD).

The company is traded on the German stock exchange (symbol: DPSGY). Since 2015, the company has made significant investments in AI vendors including for $300 million in 2018 for several applications focused on robotics and augmented reality in the internet of things (“IoT”). The company also made a $15 million investment in Boston Dynamics earlier this year.

A recent LinkedIn search lists 507 data scientists currently employed at the company.

This article will examine how DHL’s use of AI supports its business goals is exemplified through two specific use cases:

- Optimizing order fulfillment: DHL uses machine learning algorithms and predictive analytics to help e-retailers optimize route selection and staff allocation.

- Aligning workforce skills: DHL uses skills graphs enabled with natural language processing to match needed skills to people, learning content and job roles.

Let’s first examine how DHL built an AI-powered solution to optimize the company’s route selection and allocation of its workforce.

Use Case #1: Optimizing Order Fulfillment

According to DHL, the COVID pandemic lead to a steady increase in online sales, creating a problem both for electronic retailers (or “e-tailers”) and logistics companies. Household staple items like food, drugstore items, and medications were in particular demand, creating supply bottlenecks.

To overcome these difficulties, DHL Supply Chain tasked its data team with developing and adding newer forecasting and analysis algorithms to its Resilience360 platform (now Everstream, a DHL subsidiary).

The stated purpose of the algorithms was to “optimize warehousing and processing of online orders for major e-sellers.” The company wanted to eliminate some of the inherent uncertainty that comes with demand fluctuations.

DHL did not provide information on how the software was trained. However, given the purpose of the software to anticipate product demand fluctuations and optimize manpower, we can extrapolate on likely outcomes.

First, the training data probably consisted of vast amounts of individual product orders and their associated data. These may have included SKU, quantity, etc. Second, the logistical element of the algorithm would have mandated product tracking and workforce data. Workforce information would have required data such as the number of employees, locations, days and times worked, and their roles and locations.

The company states that the model data is collected via numerous input devices, including sensors and robots. The data is then centralized into warehouse management systems (WMS) and transportation management systems (TMS).

The data is then analyzed with ML algorithms. If the software detects potential insights and optimizations, the user is alerted to the actionable data via a notification system built into the software’s dashboard.

The following two-and-a-half minute video describes how the Resilience360 platform works:

DHL states that the software is compatible with most WMS systems and can be integrated into existing IT infrastructure. DHL claims that its algorithms have helped to improve the decision-making and order-picking processes of its customers.

Regarding business outcomes, the company claims that its new algorithm has reduced the travel distance of warehouse employees by 50 percent and increased the productivity of “individual DHL locations” by up to 30 percent.

Use Case #2: Aligning Workforce Skills

DHL wanted an automated solution that could identify skills the company would need in the future and prepare its workforce to transition to related roles. Cornerstone, DHL’s partner on the project, states that its client wanted an AI-enabled solution capable of “identifying the skills currently in the team today and uncovering potential skills that are relevant to tomorrow.”

In the following brief, 8-minute video below, Cornerstone Chief International Officer explains the benefits of the Conerstone OnDemand platform in aligning workforce skills for global brands:

The challenge, Cornerstone states, was two-fold. First, the manual curation of an internal talent pool is both time-consuming and difficult to scale. Such a solution would also be quickly outdated.

Second, the geographical distribution of DHL’s workforce made connecting to workers and offering traditional training difficult.

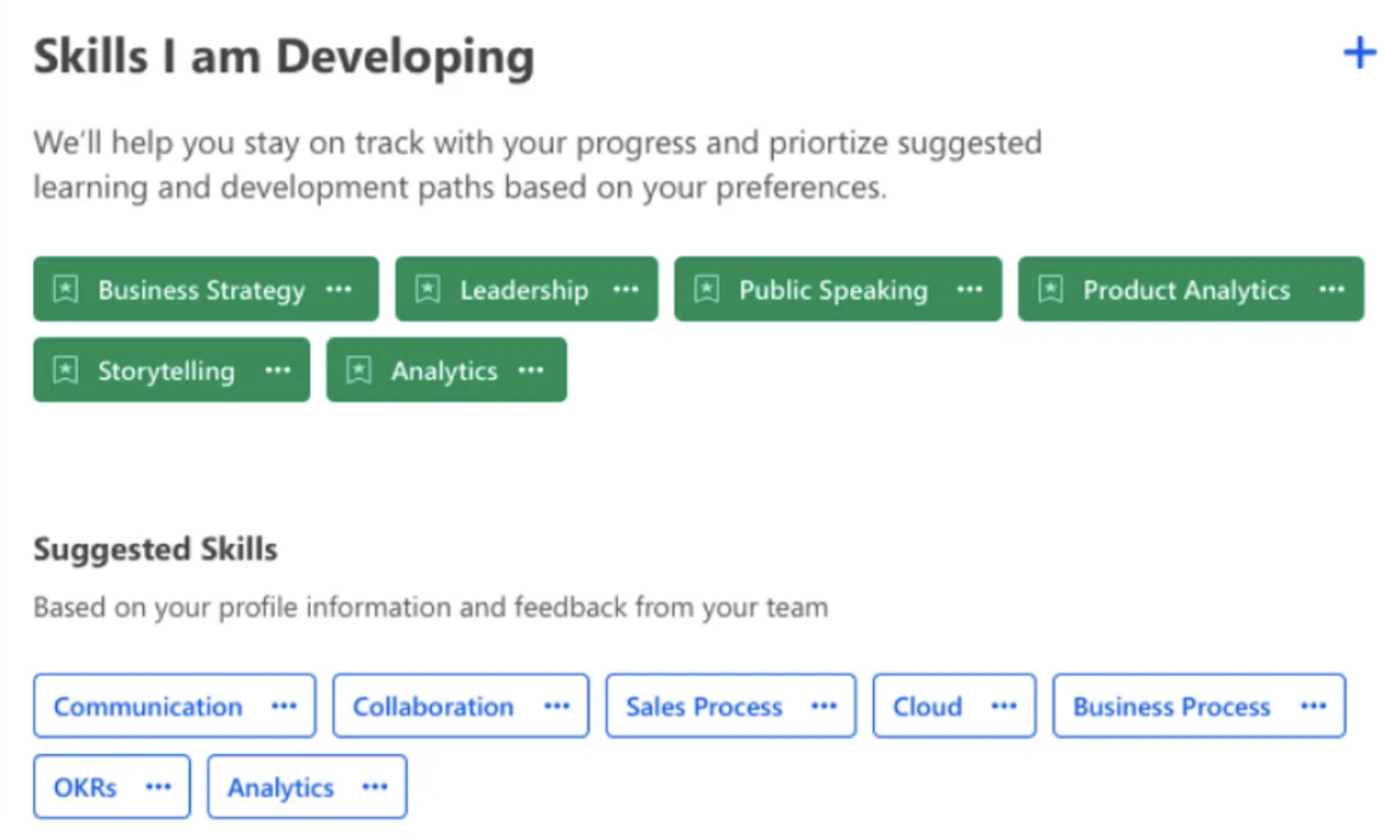

Cornerstone states that the solution was an AI-powered skills engine capable of:

- Identifying skills within the organization

- Matching internal workers to jobs requiring said skills

- Pinpoint the potential skills gaps

- Suggest training modules to account for skills gaps

A Cornerstone case study report describes the functionality of their tool to facilitate lateral and aspirational skills transfer. AI recommendations based on deeper insights into their working experience mean more fulfilling roles for “airside handlers” and warehouse supervisors.

“Once the skills are out on the table,” reads the report, “the employee [can] choose what they’d like to develop in order to move up or across into a new career path, opening up many possibilities and mapping out their future with the company.”

Cornerstone states that the key element to DHL’s solution was their Skills Graph/Skills Ontology software. Cornerstone claims that the skills graph software platform helps each employee develop individual skills profiles using their job title and resume, using natural language processing to analyze employees’ resumes and identify current skills.

The case report goes on to claim that algorithms score each candidate’s current skillset against a skills taxonomy for open jobs within the company. The company claims that its model collects taxonomy data from over 250 million external job profiles across a variety of industries and organization sizes.

The software produces an individualized profile for each candidate identifying any skill gaps and recommends associated learning content. The recommendations are made available to both the employee and supervisors.

Employee Skill Development Progress and Suggested Skills. (Source: Cornerstone)

Armed with that data, the employee is able to work on suggested training to upskill. The supervisor is able to monitor the employee’s training progress.

Concerning the results of its solution, Cornerstone claims that it was able to save DHL more than 10% in recruiting costs, equivalent to “millions of dollars.”