Food processing is one of the major manufacturing sectors in the United States. According to the United States Department of Agriculture, 16 percent of the value of shipments from all U.S. manufacturing plants comes from food processing plants. These plants employ around 1.5 million workers in this country.

For the most part, the sector is a very high volume, low margin industry. Finding new ways to gain even modest increases in efficiency can make the difference between a facility turning a profit or a loss. This is why some of the largest food processing companies are turning to artificial Intelligence technology in attempts to improve numerous aspects of the process.

This article will examine five different applications of AI in food processing to give a sense of the many ways AI is being explored by industry players in this sector (like Coca-Cola and Kellogg’s). The five artificial intelligence application categories we’ll explore in this article include:

- Sorting products and packages

- Food safety compliance

- Improved cleanliness

- Produce development

- Marketing

Food processing often involves sorting a large quantity of feedstock and careful inspection of the final product. It frequently requires the constant maintenance of equipment, storage, and work spaces in very specific conditions.

Uses of AI in Food Processing

This article will focus on AI applications that are relatively specific to food processing and preparation, but there are many more general uses of AI that directly and indirectly have an impact on the industry. For example, AI-improved weather forecasting is being used by farmers and transportation companies to improve yields and reduce shipping costs/waste that impacts costs for food manufacturers. Similarly, advances in robotics are being used in all parts of the manufacturing sector, including food processing.

We’ll begin with the first of our five AI applications below:

1 – Improved Sorting

Among manufacturing facilities, one challenge that is relatively unique to food processing plants is that the feedstock is often not uniform. Every orange, carrot, tomato, potato, apple, etc. is slightly different. A plant might need to sort millions of a particular vegetable based on size, shape, and/or color.

According to TOMRA, a leader in food sorting technology, back at the end of the 20th century, 90 percent of all food sorting was done with manual labor. Now a significant amount of that sorting has been automated. This automation created a large reduction in labor costs, a big increase in speed, and it is now improving yields.

Their systems use cameras, Near Infra-Red (NIR) spectroscopy, x-rays, and lasers to measure and quickly analyze every aspect of the vegetable as it moves along. While older automatic sorting systems were just focused on sorting the bad from the good, machine learning creates the capability to sort foods for their optimized use.

For example, potatoes can be sorted based on which ones will produce the least waste when cut into french fries and which ones would work best for potato chips. TOMRA claims their sorting and peeling solutions recover 5-10 percent of produce by improving utilization to reduce the amount of each potato that is thrown out.

Similarly, Kewpie Corporation (a major Japanese food company) is using Google’s TensorFlow machine learning to automatically detect anomalies in their diced potatoes. The potatoes will be used in baby food and are therefore subject to strict safety standards. Kewpie claims testing at its Tosu Plant found the system worked with near perfect accuracy. Previously the inspection was done manually and was a major bottleneck in their production.

Kewpie Corporation claims that following the successful test with diced potatoes, they are going to expand the use of AI inspection to other ingredients and other facilities.

2 – Improved Food Safety Compliance

KanKan, a subsidiary of Remark Holding, last month announced a seven figure contract with one of the largest state-owned enterprises in China to provide Shanghai’s municipal health agency with facial and object recognition. Their AI technology is currently being used in 200 restaurants but will soon expand to 2,000 facilities.

Cameras in the kitchen or food facility watch to make sure that individuals are wearing masks or hair protection when required by safety regulations. Violations can be caught and corrected in near real time.

KanKan is using its AI object recognition for numerous applications range from fight IP privacy to automatic checking license plates.

3 – Improved Cleaning

Researchers at the University of Nottingham with the company Martec of Whitwell are attempting to use artificially-intelligent sensor systems to improve how food processing equipment is cleaned. They claim their technology could in theory save food processing plants in the United Kingdom £100m ($133 million) a year. It would in theory reduce the amount of time it takes to clean equipment which saves money on water, energy, and time.

According to the university, cleaning accounts for 30 percent of energy and water use at food manufacturing facilities. Martec of Whitwell believes it could reduce cleaning times by up to 50 percent, enabling less downtime and more productivity.

(For readers with a more direct interest in manufacturing applications, please see our full article about machine learning in manufacturing.)

With traditional non-sensor enabled equipment it is difficult or impossible when every small part of drink processing and storage equipment has been cleaned. The current method of cleaning equipment often has no sensors or ability to see inside the equipment. As a result, companies have designed the cleaning procedure to run as long as would be necessary to deal with these worst possible scenario. Without being able to see inside the equipment that is the only way to assure it has been completely cleaned. That can require a lot of unnecessary cleaning, which wastes water and cleaning chemicals.

The company is testing their Self-Optimising Clean-in Place system. It uses ultrasonic sensing and optical fluorescence imaging technologies to feed information to an AI program to monitor the amount of food and microbial debris in the equipment. The AI will self-optimise the process to only run the cleaning system only as long as necessary.

While we were unable to find a video to showcase Martec’s cleaning system, but the company does have the following slide deck that explains the basics of the application:

The technology is currently at the end of a 12-month feasibility study.

4 – Deciding What New Products to Make

Food processing is relatively unique in being one sector where companies can offer an effectively endless variety of options given all the flavors, spices, and ingredients that exist. Recipes can be tweaked in an unimaginable number of ways. Figuring out exactly what customers want is an enormous challenge, and companies are turning to AI to help with that process. This is just one way the sector is using AI.

Artificial intelligence is now informing one of the world’s largest food companies which new products they should create.

Across numerous restaurants and other locations, Coca-Cola has installed self-service soft drink fountains which allow individuals to customize their own drinks. Customers can use these self-service machines to theoretically create hundreds of different drinks by adding different flavors to their base beverages. The video below shows one in use.

These thousands of freestyle drink fountains, each dispensing hundreds of different drinks a day, created a massive amount of consumer preference data that Coca-Cola is using AI to analyze. The first product to come from this data was Cherry Sprite. Their AI determined that people on their own created a significant amount of cherry-flavored Sprite and that it would do well as its own standalone product.

In the coming five years, major food processors may be able to leverage recommendation engines to suggest new products and flavor combinations to customers. The low-hanging fruit for these applications will likely be high volume, low cost foods (which makes soda a logical start).

5 – Helping Consumers Decide What They Want

AI is not just being used to find out what flavor combinations people are making on their own but also to help people choose new flavor combinations. Last year Kellogg Company launched Bear Naked Custom. It lets people make their own customized granola from over 50 ingredients.

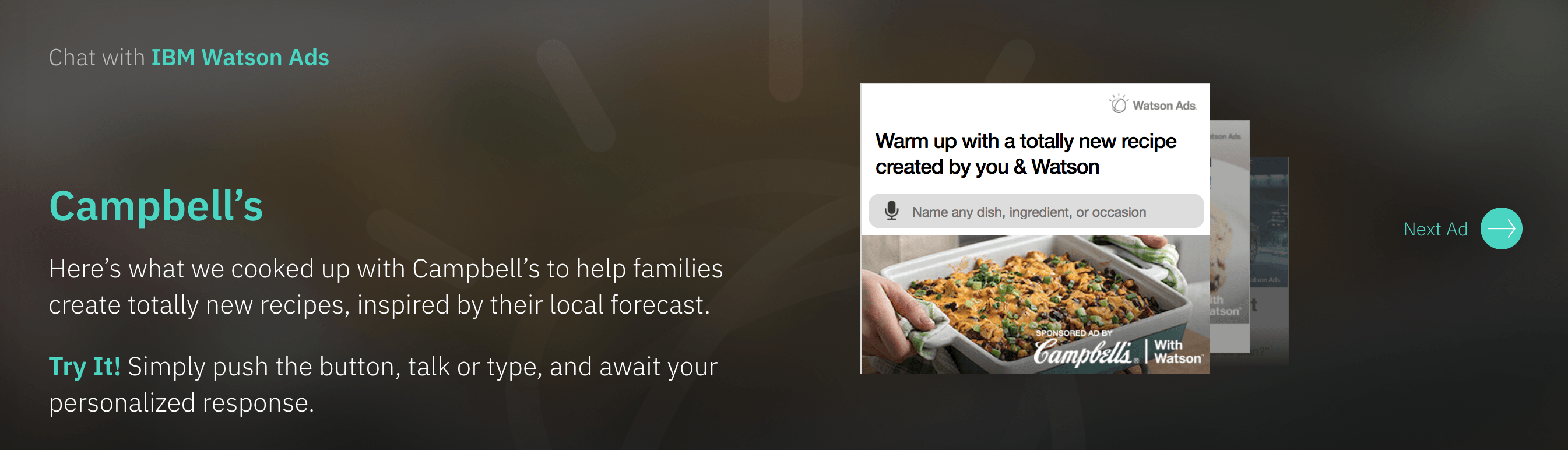

The system is powered by IBM’s Chef Watson, which has analyzed thousands of possible ingredient pairs. The AI makes suggestions about what ingredients to add to your granola and lets you know if your ingredients are likely to taste good together or not. The video explains how IBM Chef Watson works.

The AI doesn’t just help individuals make customized small batches of granola. The general data from Chef Watson about flavor combinations, information about what selections people actually make, and what combinations people re-order create a feedback loop refining what flavors people actually like. This source of data will likely provide the parent company very useful information when it comes to deciding what new products to introduce in its much larger brands.

The use of Chef Watson in food product development is still in its infancy. Where it is currently being used is in interactive Watson ads for companies like Campbell to help people choice recipes.

Concluding Thoughts

For food manufacturers, AI is being used to improve both their production process and their products. While it might not seem to be the case at first glance, food processing is actually dominated by big data problems. For problems in consumer desire, ingredient sorting, and recipe development – AI may become a viable alternative (or augmentation) to human expertise.

On the production side, every single ingredient going into a food product is going to be unique and needs to be inspected. To know if, say, a potato or an apple is usable requires an assessment of its size, shape, color, and marks (for a fundamental understanding of how machine vision works, listen to our interview with machine vision expert Dr. Irfan Essa).

For a long time only humans were capable of making these highly complex assessments at a reasonable speed, but some of that may change. Automatic systems are now able in seconds to collect hundreds of pieces of data on a single fruit and rapidly make an assessment about it. A system can gather and process all that data from hundreds of individual ingredients as they rapidly move across a conveyor belt. These systems can significantly bring down labor costs and reduce waste.

It is reasonable to expect that AI will very quickly be used more and more by food processing plants to improve feedstock sorting, find efficiencies, and increase safety. Major companies are using AI in these capacities and plan to expand their use of AI based on the results they have seen.

On the product development side, the potential combination of ingredients and ratio of different ingredients is infinite. AI is allowing to companies to both analyze consumers’ choices to find out which flavors they want and predict what flavor combinations could be most appealing.

Many major players in the food processing industry believe AI will have a real impact on the sector in the near term. The CIO of Kraft Heinz, one of the largest food processing companies in the world, is aggressively focusing on AI and robotics to cut costs throughout their operations. Kraft Heinz is really focused on these two investments to improve operations but plans to “go very deep.”

It is not really a question of if AI will see greater use in the food processing industry, just a question of how much and how quickly.

Header image credit: Berner International