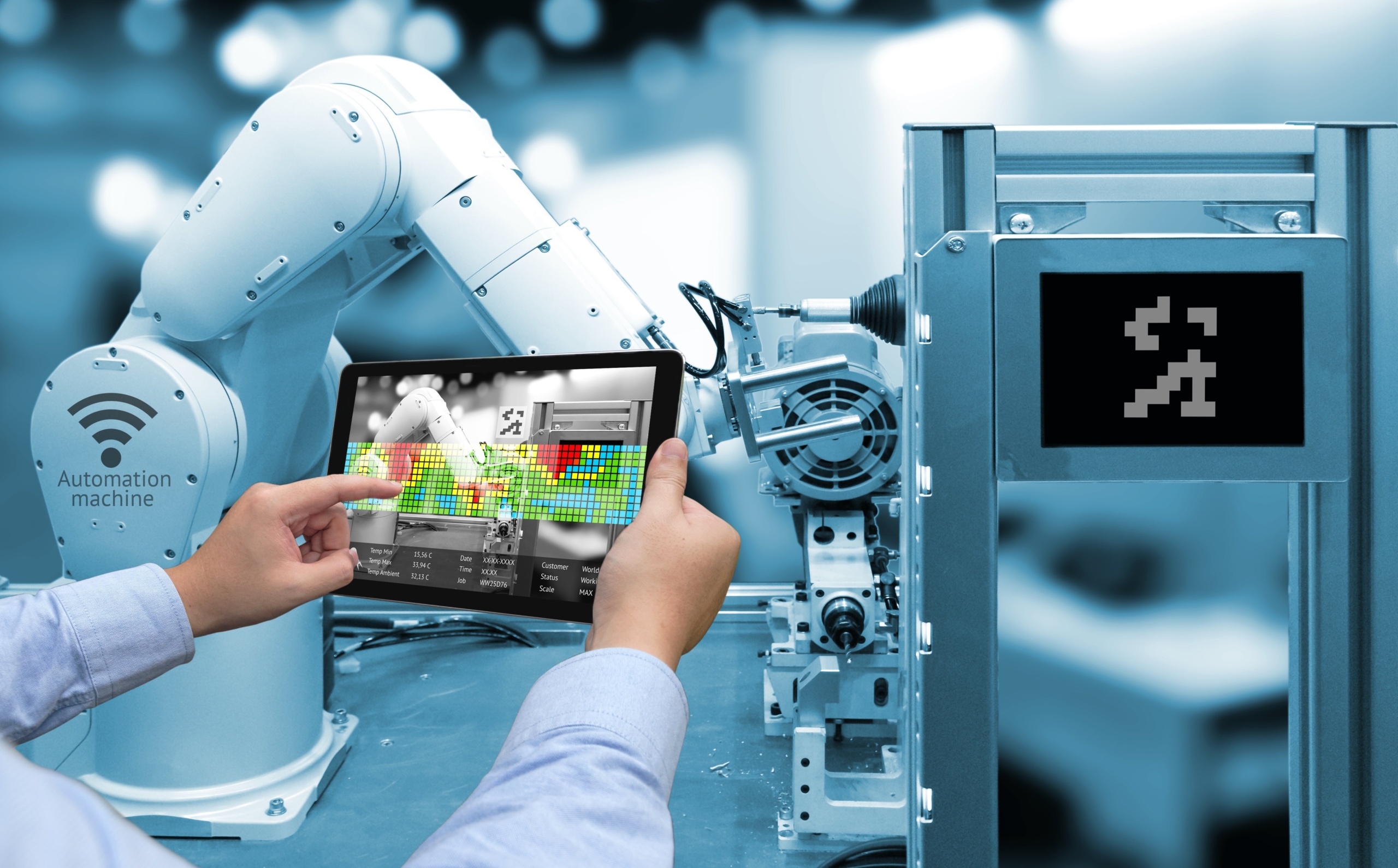

Episode summary: In this week’s episode of AI in Industry we speak with Rodney Brooks, Founder and CTO of Rethink Robotics, a collaborative robot manufacturer founded in Boston in 2008. Rodney explores robotic safety regulations and he also paints a picture of what robots might be capable of in the next five years.

Executives in the logistics and manufacturing sectors considering adopting robots will find Rodney’s insights most valuable. Rodney explores what applications will move into the realm of robotics and what application won’t in the near future and delves into what business executives need to know about human-robot collaboration before considering their adoption.

Subscribe to our AI in Industry Podcast with your favorite podcast service:

Guest: Rodney Brooks, CTO, Chairman at Rethink Robotics

Expertise: Artificial intelligence, Robotics

Brief recognition: Rodney previously earned a PhD from Stanford in computer science and went on to serve as the Panasonic Professor of Robotics at MIT for a period of 26 years from 1984 to 2010. He was also the co-founder and CTO of iRobot, the maker of the cleaning robot ‘Roomba’ before going on to be the CTO, chairman and founder of Rethink Robotics.

Big Idea

Rodney believes that the following two important trends are likely to increase in the next five years:

- “Co-bots” or collaborative robots – allowing humans and robots to share the same workspace

- Increased mobility in the factory – using the simultaneous localization and mapping (SLAM) technologies

Today, global safety standards for industrial robots often require (For example The United States Department of Labor’s Occupational Safety and Health Administration’s regulations) the use of a safety cage around the robot. In manufacturing environments, this poses several challenges like additional space requirements and costs incurred for the cage and barricades. Collaborative robots resolve this issue since they are capable of sharing workspaces with human workers. Rodney believes that the proliferation of collaborative robots has been spurred by the current stringent safety regulations around industrial robots

Rodney adds that in recent years there has been an influx of small collaborative robots from most major robotics manufacturers like ABB, Kuka and Fanuc which are embedded with sensors like:

- Image sensors which are the physical “eyes” for image recognition softwares

- Force sensors which can enable the robot to “feel” how hard they are holding workpieces in the industry or to measure the impact of a collision.

Rodney claims that collaborative robots are being deployed today in manufacturing hubs (like in China) with the aim of replacing menial and repetitive tasks.

Rodney states that in the last five years, businesses in logistics and warehousing have started to deploy SLAM technologies for their mobile robots, which can build dynamic maps and safely navigate around factory floors in the presence of other human operators. He also added that in the future as the need for more flexible automation increases, we may see a move towards more completely autonomous factories.

Given below is short two minute video refresher about the SLAM technologies as taught by Sebastian Thrun from Udacity:

Currently, collaborative robots are not very ‘dexterous’ today and are only capable extremely simple, repetitive tasks, like moving a pallet from one place to another. Safety regulations on speed and force also limit collaborative robots to handling low payloads. Yet, Rodney believes that in the next five years we will witness better tracking of human bodies with 2D and 3D cameras and similar safety systems for bigger industrial robots will be possible using dynamic vision-based tracking. Interested readers can learn more about 2D and 3D machine vision technologies in this article by the Global Association for Vision Information.

Combining SLAM, deep learning based vision systems and real-time location tags would enable industrial robots of the future to handle much heavier payloads than today’s collaborative robots without causing harm to humans. Rodney adds that although we may see the technology come to fruition in the next five years, the relatively slow evolution of safety regulations and standards to regulate these robots could be another challenge for the industry.

(Readers with a broader interest in robotics might enjoy our longer article titled: Machine Learning in Robotics – 5 Modern Applications.)

Interview Highlights with Rodney Brooks from Rethink Robotics

The main questions Rodney answered on this topic are listed below. Listeners can use the embedded podcast player (at the top of this post) to jump ahead to sections they might be interested in:

- (3.10) What is possible with industrial robots today?

- (4:55) What are some future shifts in robotic capabilities that will be valuable for businesses that have industrial robots?

- (7:27) What are some of the technologies that will be used to enhance safety around industrial robots in the future?

Subscribe to our AI in Industry Podcast with your favorite podcast service:

Header image credit: Adobe Stock