ABB is a global technology leader specializing in electrification and automation, with a history spanning over 140 years and approximately 110,000 employees worldwide. Headquartered in Zurich, Switzerland, ABB operates in over 100 countries, supported by approximately 170 manufacturing sites worldwide. In 2024, the company reported revenues of $32.9 billion and an order intake of $33.7 billion.

A core strategic focus for ABB is embedding AI into its solutions as part of its drive toward digitalization and decarbonization. It has made several strategic investments and moves in AI, large language models (LLMs), and machine learning over the past few years. Notably, in early 2025, ABB announced a minority investment in Edgecom Energy, a Canadian startup that utilizes an AI-powered energy management platform to help industrial and commercial users reduce peak power demand and optimize energy use.

This article examines two use cases of AI at ABB for manufacturing and technology leaders across sectors:

- Leveraging generative AI (GenAI) to cut costs and boost efficiency: Using GenAI and natural language interaction to proactively optimize asset health, reduce maintenance costs, and enhance industrial productivity and sustainability.

- Unifying global data to drive revenue gains and savings: Modernizing the fragmented data ecosystem with AI cloud to deliver real-time analytics, reduce inventory costs, optimize distribution, and accelerate revenue growth.

Leveraging Generative AI to Cut Maintenance Costs and Boost Efficiency

Industries operating in asset-intensive environments such as energy, utilities, chemicals, and manufacturing struggle with the high costs of maintenance, unpredictable equipment failures, and the complexity of extracting actionable insights from vast operational datasets. Research from the Department of Industrial Engineering, Faculty of Engineering, The University of Jordan highlights how downtime remains a significant risk, as do inefficiencies in asset utilization, safety incidents, and sustainability pressures.

According to the new Value of Reliability survey from ABB, over two-thirds of industrial businesses experience unplanned outages at least once a month, costing the typical business close to $125,000 per hour.

According to a release published by ABB, the company recognized the need for a solution that would democratize access to actionable insights, optimize maintenance, and accelerate decision-making across its own and client operations.

The same document mentions that ABB invested in a next-generation solution to empower industrial workforces to easily access, interpret, and act on complex asset data in real time.

According to ABB’s website, the Genix APM Copilot platform is built on top of ABB’s Genix Industrial IoT & AI Suite, in close collaboration with Microsoft and leveraging Microsoft Azure OpenAI Service. Key technical features that the company highlights include:

- Genix Industrial Analytics and AI Suite: ABB’s Genix Copilot is part of the Genix platform, which integrates industrial data from diverse sources for analytics and insights.

- Generative AI Copilot powered by Azure OpenAI Service: ABB claims that Genix Copilot uses generative AI, specifically leveraging Microsoft’s Azure OpenAI Service. If implemented as described, the system would enable natural language interaction for users to derive insights and recommendations from operational data.

- Natural Language Interface: Users access Genix Copilot through a conversational interface, allowing them to pose questions and receive actionable, context-aware answers in plain language.

- Integration with Operational Data: The Copilot connects to real-time and historical plant and asset data for analysis and reporting.

- Conversational Interface: Maintenance engineers, operators, and managers can ask questions like “What is the status of carbon emission across the plant?” or “Summarize asset anomalies from last shift?” with instant, context-aware responses accessible role-wise from the shop floor to boardroom.

ABB claims that the introduction of ABB Genix APM Copilot transforms workflows by enabling staff from the shop floor operators to executives to access real-time, actionable insights and recommendations simply by conversing in natural language with the system.

Additionally, the generative AI layer rapidly analyzes operational data from multiple sources, delivers instant answers to asset health or incident queries, flags anomalies, and suggests remedial actions, all within a unified interface.

ABB and Microsoft report that customers running the Genix platform have seen up to:

- 40% reductions in operations and maintenance costs,

- 30% improvement in production efficiency, and

- 25% improvement in energy and emissions optimization.

Unifying Global Data to Drive Revenue Gains and Savings

Data fragmentation in ecosystems leads to challenges in integrating, analyzing, and extracting value from data. Research from Harvard Data Science Review highlights that such fragmentation creates risks of inefficiency, conflicting data truths, and lost opportunities for comprehensive insights.

According to the 2019 Enterprise Strategy Group (ESG) Research Insight Paper from TechTarget titled “Mass Data Fragmentation Is Quietly Killing Digital Transformation Efforts,” organizations spend on average 42% of their IT administrators’ daily tasks managing fragmented data. The workflows involved include handling secondary data, copies, and applications scattered across on-premises and cloud environments.

According to a case study published by Snowflake, ABB faced significant data management challenges due to its complex technology ecosystem, which included 40 geographically dispersed ERPs, 25 data warehouses, 4,000 applications, and 15 SAP Business Warehouse instances.

The fragmented environment caused long data consolidation cycles (up to one month), leading to outdated information and analytical delays. Previous attempts, including a Hadoop solution, were costly and inefficient, consuming 50% of the team’s capacity on maintenance rather than building solutions.

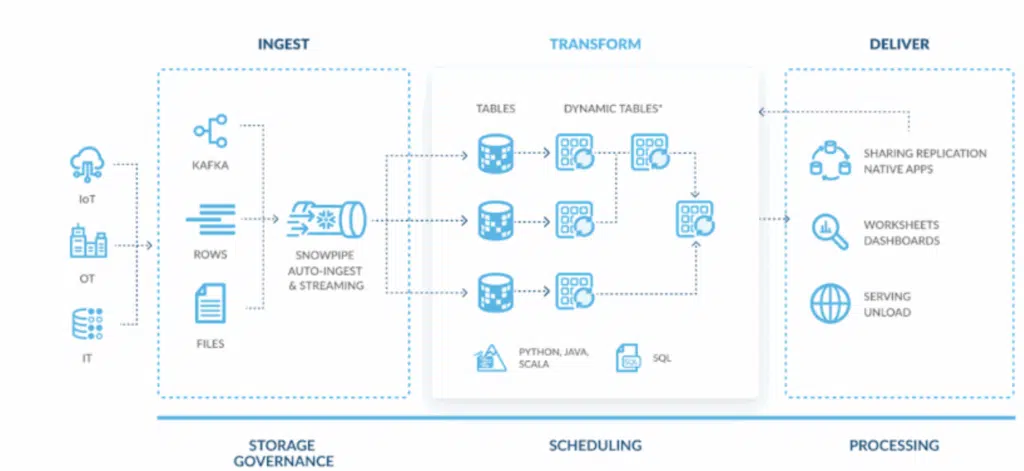

ABB needed a unified, scalable, and efficient data platform to enable timely and data-driven decision-making across its global operations. According to use case documentation from ABB, they adopted Snowflake AI data cloud for manufacturing to help solve these problems.

The objectives of this partnership were to:

- Modernize ABB’s data infrastructure for real-time, unified access across 100+ countries and 20 divisions.

- Accelerate data-driven decisions to optimize supply chain, pricing, and distributor operations.

- Cut costs by reducing excess inventory and streamlining order management.

- Drive innovation and scalability with a data-first approach for thousands of users and vendors.

The case study mentions that data cloud supported near real-time Change Data Capture (CDC) to replicate data with minimal overhead and leverages SQL-based data processing skills readily available in the market.

ABB leveraged Snowflake’s advanced analytics capabilities to run complex pricing algorithms, distributor optimization dashboards, and predictive analytics. These analytics utilize data models powered by AI and machine learning technologies, either native or integrated with Snowflake, to optimize pricing decisions across multiple products and sectors. They also recommend optimized ordering patterns to distributors, thereby minimizing inventory and order processing costs.

Snowflake claims the following business results for this partnership:

Distributor order optimization led to $1.4 million in operational cost savings, a 22% reduction in split case orders, a 36% increase in order volumes, and a 45% growth in total purchase order value, improving sales efficiency.

ABB saved approximately $4.5 million per week in canceled inventory orders—over $200 million per year—by avoiding unnecessary purchases during the pandemic.

Pricing algorithm enhancements drove a $900 million revenue increase in the U.S. through better balancing of order volumes and profit margins.

Snowflake claims the following business results for this partnership:

- ABB saved approximately $4.5 million per week in canceled inventory orders—over $200 million per year—by avoiding unnecessary purchases during the pandemic.

- Pricing algorithm enhancements drove a $900 million revenue increase in the U.S. through better balancing of order volumes and profit margins.

- Distributor order optimization led to $1.4 million in operational cost savings, a 22% reduction in split case orders, a 36% increase in order volumes, and a 45% growth in total purchase order value, improving sales efficiency.