Global spending on utility customer information systems (CISs) and analytics is expected to total nearly $37 billion from 2014 to 2023, according to a report from Navigant Research. Some of the top utilities companies in the United States have been using predictive analytics to enhance operations, cut costs and improve customers’ experience.

Utility spending on customer engagement is estimated to grow from $636 million in 2016 to $774 million in 2022, as per the Navigant Research report.

In this article, we examine 4 of the largest North American utilities companies in an effort to determine trends and initiatives around AI in public utilities use-cases. Companies covered including:

- NextExtra Energy

- Duke Energy

- Southern Company

- Dominion Resources

For each firm, we provide background information including market cap, headquarters location, and reported revenues, in addition to listing their present AI initiatives.

1 – NextEra Energy

With a market cap of $72.05 billion as of February 2018, NextEra Energy was among the top electric utilities firms in the US, according to the company’s annual report. The renewable energy company has invested more than $23.6 billion in wind projects in 20 U.S. states and four Canadian provinces.

The company, which is based in Juno Beach, Florida, claims to be using machine learning across its operations to cut costs, improve efficiency and boost productivity.

Predictive Analytics to Keep the Power On

NextEra’s power generation division (PGD), which includes its fossil, solar and wind facilities, created generation analytical services team in 2002-2003, with the predictive analytics division being a recent addition. Operations and maintenance are two key areas that benefit from the tools and models developed by the predictive analytics team.

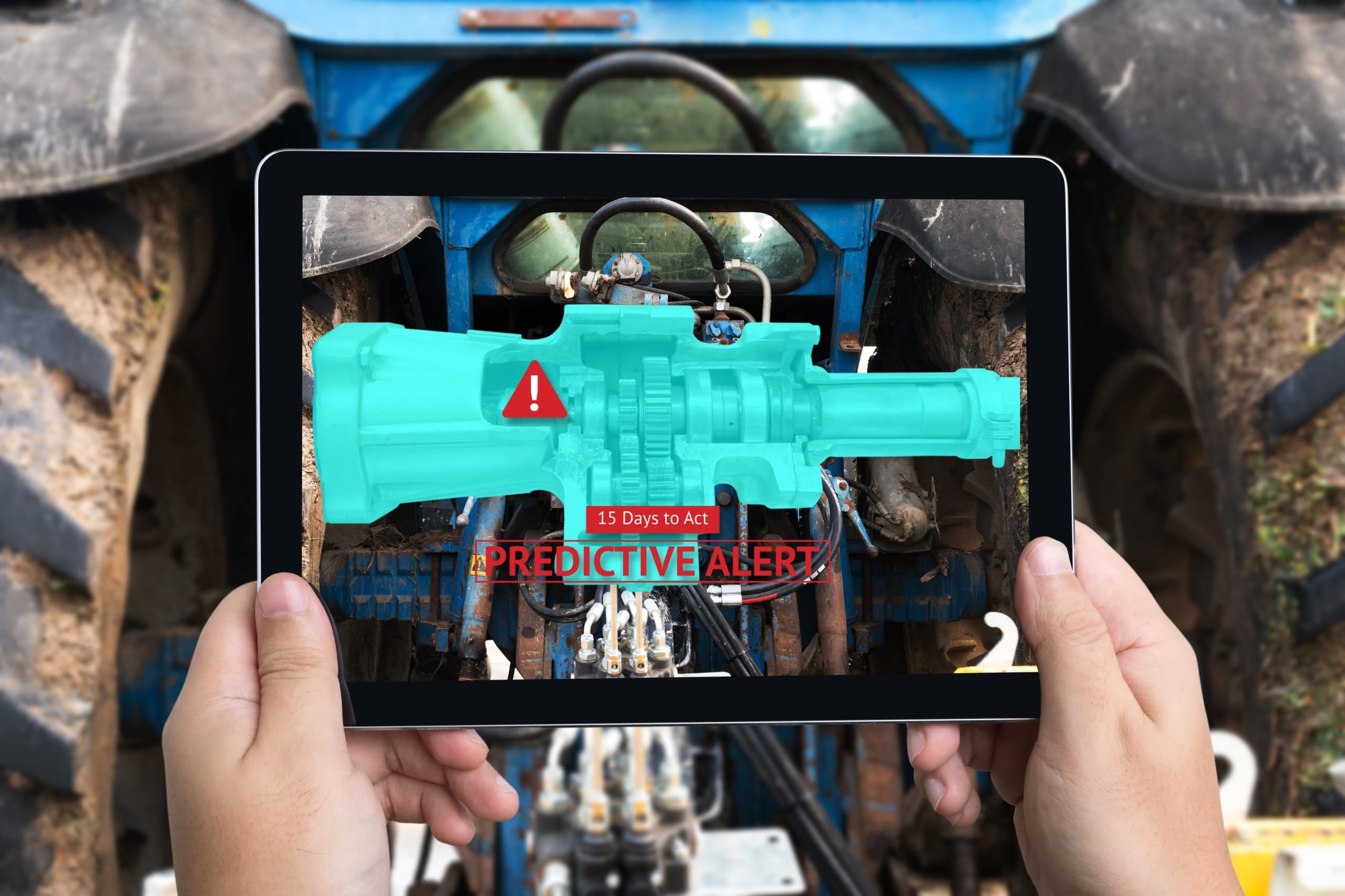

Equipment is continuously monitored by AI-driven tools to ensure smooth operation and prevent unexpected disruption. The tools can detect emerging issues and assist engineers with analysis to improve efficiency.

For example, at the Florida Power & Light (FPL) Company’s West County Energy Center (FPL is a subsidiary of NextEra Energy), predictive analytics, based on machine learning models, identified unusual patterns in the functioning of the combustion turbines in the plant. The information was shared with FPLs inspection team which discovered that the turbine had suffered internal damage, that could have been aggravated if not for the early detection.

“Improving predictive tools is a big focus for us this year, and the team has really delivered so far with the new pattern recognition and learning applications. We’re already getting great insights from the data by using these tools. Now, our challenge is to prioritize and deploy it to the types of equipment that will bring the biggest value to PGD,” – Marty Domenech, Senior Director of PGD Analytics and Engineering Valuation

Machine Learning for Wind Power Generators

NextEra, which operates more than 100 wind farms in 19 states and Canada, claims to use machine learning and predictive analytics to boost the functionality of wind turbines and reduce maintenance costs. The software, developed by Space Time Insight, helps with performance optimization, real-time diagnostics and troubleshooting, and maintenance crew scheduling, Space Time said.

SpaceTime creates optimal schedules and routing for maintenance crews and automatically sets up work orders in the system.The platform claims to use use ML-based analytics and considers real-time, variables such weather and traffic to optimize operation and maintenance activities, which drastically cuts costs.

Here is a short video from Space Time Insight on how their platform can help analyze and control grid events including outages and maintenance schedules. IT and operational data is gathered from phasor measurement units (PMUs – a device that can measure current and voltage by amplitude and phase at selected stations of the transmission system using a common time source for synchronization).

Space Time claims that their analytics platform uses reinforcement learning to optimize real-time processes and can undergo supervised training from grid-variable datasets to minimize maintenance costs or outages.

NextEra’s ControlComm – Managing Energy Demand

NextEra’s ControlComm is built on a communications platform built by AutoGrid, an energy infrastructure vendor. AutoGrid helps business customers reduce energy bills by adjusting their energy consumption manually or with an automated solution, during times of peak energy demand or high wholesale electricity prices.

AutoGrid claims that its technology uses petabytes of data from smart meters, sensors and other third parties to predict electricity demand and power outages. While the company isn’t explicitly clear in the press release (linked above), it’s likely that AutoGrid collects this data through its clients (like NextEra), and derives insight from patterns that it finds with energy use, power failures, specific sensors on different kinds of equipment, etc. The firm claims that machine learning is used in this process, although at the time of writing we could not confirm the specifics for this.

The firm may – for example – notice that specific patterns of energy use during a snowstorm are more closely correlated to outages. Determining this correlation in a number of winter storms may help prevent (or better handle) further outages.

“With AutoGrid, we are leveraging technology to enable customers to develop intelligent curtailment plans using forecasts developed with advanced analytics and the latest market information,” Brian Landrum, President NextEra

2 – Duke Energy

Charlotte, North-Carolina-based, Duke Energy, which serves 7.4 million customers in the United States, has been considered next.

The company has more than 60 plants in six states – which might potentially face maintenance and downtime issues, affecting customer relationships. Duke Energy has been using the industrial internet of things (IIoT) to identify problems early and in turn save the company millions in damages.

SmartGen Program – Monitoring, Predictive Analytics

After losing $10 million due to a major power failure, Duke Energy underwent a major initiative to improve its equipment and infrastructure with sensor data – in an effort to better prevent future failures. Industrial IoT reports:

“This [initiative] includes online sensors, a data management infrastructure, and equipment health and performance monitoring. Duke Energy developed monitoring, predictive analytics, and diagnostics infrastructure, providing a significant advancement in:

- Remote equipment monitoring

- Smart diagnostics and prognostics

- Data integration & visualization

- Enhanced reliability process (consistency across the company)

- Zero event operations (safety and environmental)”

The initiative – referred to within Duke as the “Duke Energy SmartGen Program” – will begin with easier sensor and infrastructure investments, and then move up to more resource-intensive upgrades. The company claims to have implemented over 30,000 sensors across 50 carefully selected power plants thus far, together with Schneider Electric’s Avantis PRiSM APR software for “asset health monitoring and alert notification.”

Schneider claims that PRiSM software uses machine learning, and allows Duke to develop data models, avoiding the need for Duke to develop complex engineered models themselves. The goal of this system is to pick up on patterns in sensor and energy plant data to help Duke focus on the areas most critical to its maintenance and performance.

In the 17-minute presentation below, Bernie Cook, former Director of Maintenance and Diagnostics, explains the implementation of the sensors, the PRiSM software, and the actual use of that software in Duke’s operations:

Bernie uses an example of a particular turbine which began sending off slightly unusual vibration sensor data through PRiSM. “That’s what it does, it patterns what normal behavior is, and tells you when small changes happen.” This anomaly was brought to the attention of Duke Energy’s engineers.

As it turns out, some bolts had come loose inside of the “flow sleeve” (a section of a turbine that directs the steam flow), and had begun making slight contact with the blades of the turbine itself. Bernie explains that without sensor data that was trained on “patterns of normal”, this failure may not have been picked up and fixed.

According to Duke Energy, the SmartGen program saved them more than $4.1 million by triggering an early warning when one of Duke Energy’s steam turbines had begun to malfunction. Bernie adds that a total of 384 finds during three years has saved Duke $31.5 million in repair costs.

Duke Energy also uses SparkCogntition’s AI algorithms to safeguard its multi billion-dollar turbines by predicting potential disasters and shut down. SparkCogntition has been able to improve failure forewarning for the largest pump manufacturer to five days from only a few hours, according to a Frost & Sullivan report. Although, specifics of the implementation were unclear at the time of writing.

Personalizing Energy Usage with Chatbots

Duke Energy in partnership with Tendril launched the MyHome mobile utility app in June 2016. Chatbots help customers get answers to their queries faster and more efficiently with AI-powered automated responses (for more in-depth analysis on chatbots, see our full article titled “7 Chatbot Use Cases That Actually Work“).

The app collects 300 data elements, including the home’s footprint, weather, etc., and processes them to provide customers with energy efficiency tips, savings projections and messages that created to solve specific issues.

The Tendril marketing video below showcases how the MyHome app supposedly lets users get automated energy consumption reports for their homes:

3 – Southern Company

The utility holding firm, with subsidiaries including PowerSource, Georgia Power and Southern Company Gas, is one of the biggest electricity producers in the Southeastern region of the United States, with a capacity of 39,000 megawatts of capacity serving 4.1 million customers. The company has been employing analytics across its businesses to improve operations, cut costs and enhance customers’ experience.

Providing Customers Greater Control Over Energy Use

In June 2017, Southern Company subsidiary PowerSecure and Advanced Microgrid Solutions (AMS) said they would jointly develop and deploy behind-the-meter distributed energy resources across the United States, through AMS’ Armada platform, identifying opportunities for grid services and revenue stacking.

“This strategic relationship between PowerSecure and Advanced Microgrid Solutions will uncover new ways for Southern Company to deliver value for energy consumers,” Southern Co CEO Thomas Fanning

PowerSecure aims to provide customers greater control over their energy and outstanding service across multiple technologies. AMS will use its advanced analytics and co-optimization platform to lower energy expenses for customers while providing cost-effective grid services to utilities, the companies said.

Predictive Analytics for Collections

Southern Co has been employing predictive analytics to create a more streamlined collections process, according to an EnergyCentral report. Utilities use analytics to help them enhance sensor data, analyze smart grid data and study customer behavior so they can uncover opportunities for improvement and make more precise decisions.

“In this era of Big Data, energy companies are expected to understand their customers better and use resources more wisely,” Hong said. “Achieving this goal can require advanced analytics, including forecasting and optimization, as well as integrated data management.” – Professor Tao Hong, Associate of the Energy Production and Infrastructure Center at the University of North Carolina – Charlotte

4 – Dominion Resources

Richmond, Virginia-based Dominion Resources Inc, which operates four energy businesses – Dominion Delivery, Dominion Energy, Dominion Exploration & Production and Dominion Generation, has created a grid-optimization subsidiary, Dominion Voltage Inc (DVI), to help manage its power grid.

DVI helps Dominion address issues including increases in distributed generation, aging infrastructure, the need for new forms of energy efficiency/demand response, and a changing regulatory environment.

Grid Analytics and Control

DVI’s solutions plan, manage and validate investments in grid-optimizations while delivering significant savings, the company said.

The business provides solutions for energy efficiency, demand response, Volt/VAR control, and renewables integration, which helps the customer control the grid instead of the other way around.

The patented technology helps utilities mange the grid using advanced metering infrastructure (AMI), or a smart meter, which has two-way communications with the meter and central system, recording consumption of electric energy hourly. This helps Dominion to monitor usage and with billing.

Managing Distributed Energy Resources

DVI also uses the EDGE Analytics dashboard, which claims to provide visibility into cost, energy and carbon savings obtained through grid optimization.

Part of the dashboard is the EDGE Stabilizer, which helps with voltage optimization at utilities with high levels of distributed energy resources (DER) such as solar and wind, the company claims. The technology also combines detailed weather forecasts to predict voltage fluctuations on a circuit-by-circuit basis. Although further details about how the optimization is achieved using AI was still not clear at the time of writing. In a quote from a recent interview with Power Engineering:

“Market forces are significantly increasing the amount of DER, and utilities need cost effective ways to safely and efficiently integrate DER into their grids,” Todd Headlee, Executive Director of DVI

Related Articles on Emerj

If you enjoyed this article about the utilities industry, you might also enjoy our other coverage in heavy industry sectors:

- Artificial Intelligence in Oil and Gas – Comparing the Applications of 5 Oil Giants

- AI in Mining – Mineral Exploration, Autonomous Drills, and More

- Machine Learning in Manufacturing – Present and Future Use-Cases

- AI in Agriculture – Present Applications and Impact

Header image credit: Adobe Stock