Lockheed Martin offers numerous artificial intelligence solutions to the US military. The company claims to help military operators effectively complete both routine and critical missions with less risk of endangering the lives of military operators. In 2017, Lockheed Martin reported $51 billion in revenue, $35.2 billion reported from contracts with the US Government. This makes Lockheed Martin the largest contractor for the US military and the largest defense contractor in the world.

Formed by the merger of Lockheed Corporation and Martin Marietta in 1995, Lockheed Martin is a publicly traded company that employs over 100,000 people. Dana (Keoki) Jackson is CTO at Lockheed Martin. He holds a PhD in Aeronautics and Astronautics from MIT. Jackson previously served as a NASA Research Fellow before his professional career at Lockheed Martin.

We’ll begin by providing an overview to Lockheed Martin’s current AI initiatives, and we’ll end this article by examining four of their applications in depth:

An Overview of Lockheed Martin’s AI Initiatives

Advanced Technology Laboratories (ATL) is a subsidiary of Lockheed Martin where much of its advanced testing is conducted. ATL lists its current AI initiatives on their website. Some of their initiatives have their roots in research and development that dates back to 1995.

Although the largest US Military contractor in the world, Lockheed Martin’s AI initiatives seem to be the least far along, with little real-world traction and combat-ready use cases. This could also be an indication that the current machine learning initiatives at Lockheed Martin are classified projects and thus cannot be publicized. A large majority of the older AI programs detailed on Advanced Technology Laboratories’ website that have been published all seem to integrate with current systems as add-ons to already established software or systems, in efforts to boost the decision-making ability of human operators and regular computer programs. This is in contrast with the BLADE contract that is a new military initiative centered around technical creations meant to stand alone in the field.

Lockheed Martin’s CTO also announced the establishment of their AlphaPilot AI Innovation Challenge. This innovation challenge, coupled with the low visibility of AI on Lockheed Martin’s company website, may help further suggest artificial intelligence initiatives are not of the highest priority at Lockheed Martin. Seeking aid from private sector competitors who feel they can meet the challenge to help boost their development efforts rather than find, hire, and keep the requisite talent themselves.

AlphaPilot will challenge teams of up to 10 participants each to design an artificial intelligence framework, powered by the NVIDIA Jetson platform that is capable of flying a drone without any human intervention or navigational pre-programming. Lockheed Martin is looking for the autonomous system to, ultimately, outperform manually operated competitive drone racing teams. To start, the autonomous drones will race head-to-head through complex tracks in the Artificial Intelligence Robotic Racing (AIRR) Circuit, shown below, starting in 2019. Lockheed Martin is reportedly offering over $2 million in prize payouts to the winnings teams.

Lockheed Martin plans to utilize the winning platform to aid their own drone platform research and development efforts for both air and space drones. As Lockheed Martin’s primary customer is the US Department of Defense, Lockheed Martin applying the discoveries from this content to the military applications of smarter and more sophisticated autonomous drone technology is nearly a given.

This report on the military applications of AI at Lockheed Martin covers the following four applications:

- Behavioral Learning for Adaptive Electronic Warfare system (BLADE) – Detection and characterization of new wireless communications threats.

- Mission Effectiveness and Safety Assessment (MENSA) – Improving drone navigation and contingency planning.

- Speech Understanding System, Intelligent Environment (SUSIE) – Improved speech recognition and natural language processing.

- 3D Printing – Quality improvement for robotic 3D printing systems in the US Navy.

The intent of this report is to illuminate the variable military applications of Lockheed Martin’s products with AI technologies that the US Department of Defense currently has the capability to utilize in combat scenarios.

We’ll begin by examining Lockheed’s applications one by one, beginning with BLADE:

BLADE – Adaptive Electronic Warfare

The Defense Advanced Research Projects Agency (DARPA) of the US military awarded a $29 million contract to Lockheed Martin for the creation of the Behavioral Learning for Adaptive Electronic Warfare system (BLADE). DARPA suggests Lockheed Martin’s program will detect and characterize new wireless communications threats, such as radios or command and control networks and disable them. In the phase 3 field testings section of the contract, DARPA has also suggested BLADE can respond to new countermeasures from enemy radio communication threats attempting to re-engage themselves.

Neither Lockheed Martin nor DARPA state the system’s output, merely reporting on the results it intends to drive on the battlefield. We were unable to find detailed information on what the system receives as input, how the algorithms actions are displayed to the user and how the system uses its machine learning algorithm to generate the desired result. This may be intentionally suppressed information. Spreading such details would allow enemies to the US military to gain information on the inner technical workings of the BLADE algorithm. If that were the case, countermeasures to the BLADE could hypothetically be created and render the system useless.

The strategic implications of BLADE go beyond the disruption of enemy communications via wireless means. Often, cell phones can be used as “RF triggers” to wirelessly detonate improvised explosive devices. BLADE could disable the wireless communication signal of cell phones attempting to detonate an IED, resulting in the neutralization of the explosive and reducing casualties.

In 2011, ATL cited Vikrum Sardana as the lead Project Manager on the BLADE program however, we could not find any information on Vikrum’s academic and professional background.

MENSA – Drone Navigation and Planning

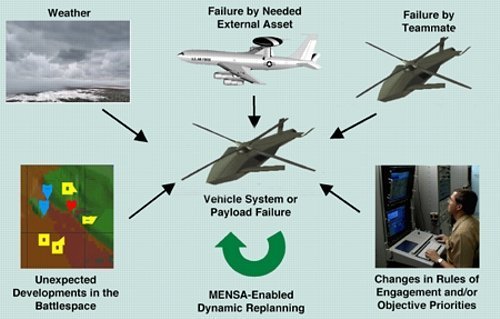

Advanced Technologies Laboratories (ATL) of Lockheed Martin has developed a machine learning software system called MENSA (Mission Effectiveness and Safety Assessment). ATL claims MENSA can help the US military boost its autonomous drone program by allowing the drones to keep track of listed mission requirements and assess the impact of every detected contingency to determine if it affects the vehicle’s safety or its mission. The MENSA system detects anomalous events that may affect the key variables that would result in mission success or failure.

The machine learning method by which this system can occur is not explicitly outlined publicly by Lockheed Martin, but we can infer this system is using a mix of predictive analytics and machine vision. Machine vision would be required for data analysis requiring detection of real-world objectives, such as tracking a moving target or correctly identifying an individual amongst others.

The predictive analytics aspect of the software seems to calculate the likelihood of mission success in situations different than the described mission environment or parameters. For example, a damaged rotor blade might cause the drone to travel 10 mph slower than its design intends.

We can infer the machine learning model behind the software was trained on thousands of recorded military drone operations and their outcomes. The data would then be run through the software’s machine learning algorithm. This would have trained the algorithm to discern which data points correlate to increasing or decreasing projected mission success. The software would then be able to predict if the current factors the drone is involved in would result in a successful mission if continued.

We could not find footage of drones utilizing the MENSA system. To our knowledge, the MENSA system has not been utilized in combat scenarios for the US Department of Defense.

SUSIE – Speech Understanding / NLP

Speech Understanding System, Intelligent Environment (SUSIE) was commissioned for development by DARPA in the late 90’s, and Lockheed Martin claims it can help users get information and be notified of events by voice request using natural language processing. Lockheed Martin claims their conversational interface can integrate into audio communication and computer systems on a command station of a vessel or in a research lab.

We can infer the machine learning model behind the speech recognition software was trained first on hundreds of thousands of relevant speech requests, such as “notify me if the starboard generator temperature changes” in various accents and inflections from various types of people. The machine learning algorithm behind the voice recognition system would then transcribe those speech requests into text. Human editors would then correct the transcription and feed the edited text back into the machine learning algorithm. This would have trained the algorithm to recognize and correctly transcribe these speech requests.

This transcription could then be “read” by the software, and the software would be able to generate a report for the user or notify them of an event. It is unclear if SUSIE has the capability to respond to users with preprogrammed speech. Unfortunately, there doesn’t seem to be a video available demonstrating the software.

Lockheed Martin claims to have developed SUSIE systems in a number of military domains, including Marine logistics and battlefield casualties reporting using SINGCARS radios and on ship status monitoring through the on-board intercom. Advanced Technology Laboratories claims it “is the only institution to develop spoken language understanding technologies that are sufficiently robust enough to be successfully field tested and demonstrated in harsh military environments”; however, our research has yielded no current examples of the software at work in combat scenarios.

3D Printing and Quality Improvement

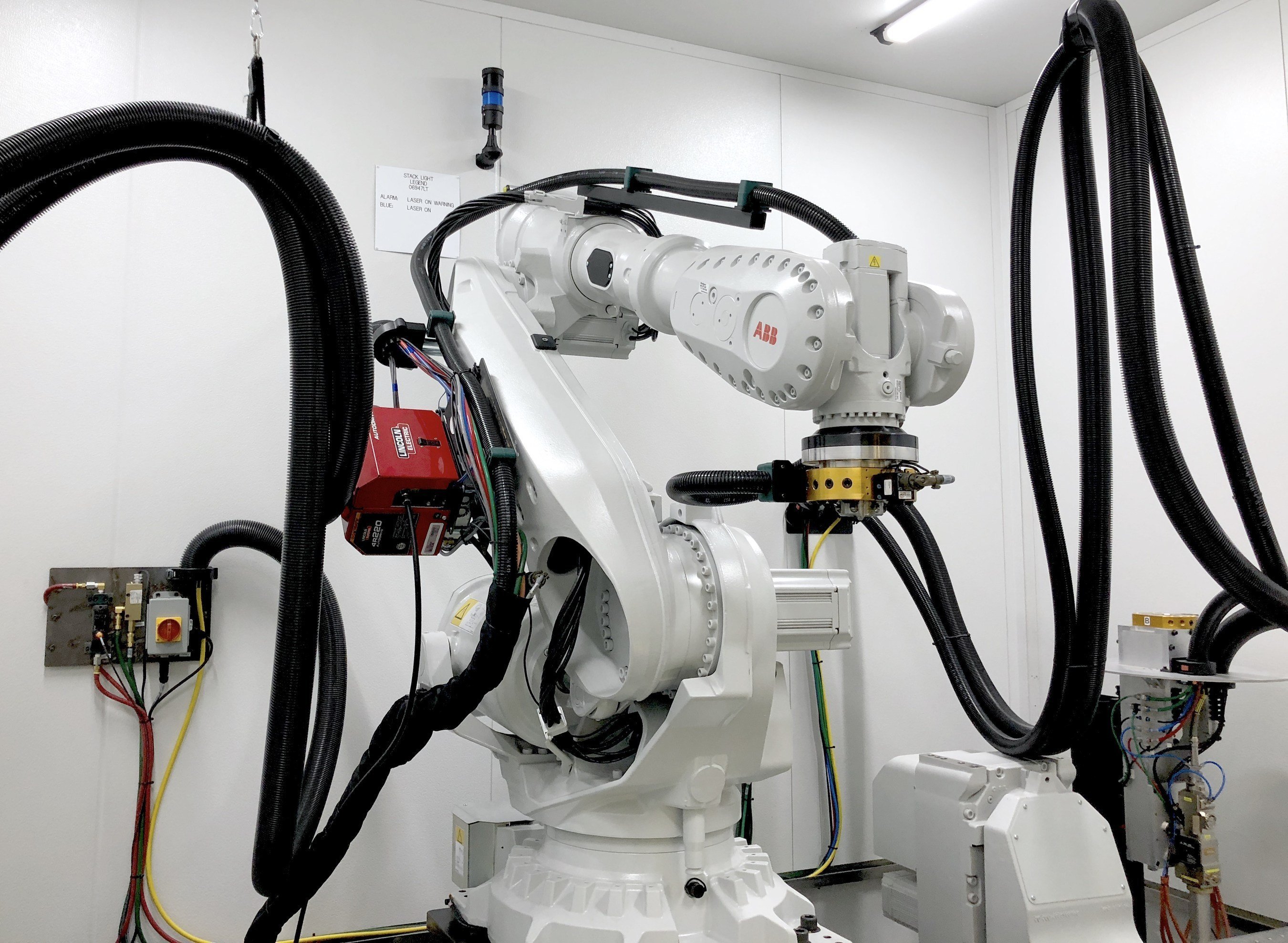

Lockheed Martin has partnered with the Office of Naval Research to fund a $5.8 million dollar contract. Lockheed Martin claims it can help manufacturers in the field build replacement parts with a machine learning-aided 3D printer. By combining the current 3D printing technology at the disposal of the Navy and Lockheed Martin’s machine learning algorithm will be able to learn and observe its printing process inefficiencies and then iterate on its printing process for improved part quality. Lockheed Martin states their AI can integrate with the 3D printing robotics systems used in the US Navy.

Lockheed Martin analyzed common designs utilized in the 3D printing process. Parts can sometimes be manufactured with blemishes that might not be easily identified. Selecting the most optimal design could mitigate the occurrence of these blemishes. Lockheed Martin indicated that a team from their company trained the algorithm. The team measured and logged the quality of printed parts, assigning a score to key features of the part. The team then feeds the labeled score data into the machine learning algorithm.

It’s likely the AI was trained on these scores as well as data on the 3D printing designs. This would allow the machine learning model to determine which designs correlate to the highest scores. When a user uploads the part’s digital schematics into the printing software, the machines learning algorithm makes decisions on how to print that part as to ensures the best-known pattern of printing is chosen.

The strategic military advantages of 3D printing could be impactful to supply chain management. Large military sea vessels like an aircraft carrier can be outfitted with a 3-D printer and manufacture replacement parts for other smaller military craft or operations during deployment in the field. A 3D printer-equipped vessel could simply print the needed part rather than send a delivery vessel with a replacement part to the ship in need.

As another example, a military vehicle in the desert equipped with a printer could print its own quality replacement parts, thus eliminating the need for the vehicle to be abandoned, an operation to be delayed while a replacement part is transported to the disabled vehicle, or the broken vehicle to be towed back to a military facility that has the needed parts.

Header Image Credit: NPR