Tech Provider: Predii – a company which specializes in building AI platforms designed for repair and maintenance services in the industrial equipment and automotive sector

Client: Snap-on Inc. – an OEM of high-end tools and equipment for the automotive, heavy duty, equipment, marine, aviation, and railroad industries.

Industry: Transportation

Function: Business Intelligence and Analytics

Tech Provider Contact Person: Sierra Stanton

Snap-on’s repair systems and information division was looking to monetize data that they were collecting from their service operations. The company collaborated with Predii for a pilot project which eventually turned into a solution offering called Predii Repair Intelligence. The problems and actions taken for this case study have been segmented into 3 parts.

Problem 1: OEM Manuals

The original equipment manufacturers (OEMs) of vehicles produce detailed product manuals each specific model type in their fleet (like different models of cars, trucks etc.). It is common in the automotive industry for these manuals to be over thousands of pages long with exceedingly detailed information about vehicle specifications, diagnostic procedures and troubleshooting. Snap-on wanted to create an easily queryable database to help technicians effectively utilize these lengthy manuals.

Actions Taken

Predii used a natural language processing platform configured by using well-structured data from manuals of vehicles to automatically tag and categorize the ‘key concepts’ from each manual. This enabled the Snap-on team to quickly search through these manuals digitally and built a foundation for targeted contextual searching and extraction.

For example, a repair technician might phrase his search query as “Ford oil-filter” and receive an extracted snippet of oil-filter specifications for all ford vehicle models. Although at the time of writing Predii did not provide further details on how the NLP platform was configured to automatically tag and categorize the information in the manuals.

Problem 2: Telemetry Data

Automotive vehicles are embedded with thousands of sensors (that track temperature, pressure, speed, rotations per minute etc.) to monitor vehicle conditions and enable technicians to diagnose maintenance issues in case of malfunctions or failures. For example, when a car comes in for repair service related to internal heating and cooling systems, heat sensor data can potentially offer useful insights for resolving the issue.

The data gathered from these sensors (collectively called telemetry data) is often collected at a high rate of around millions of data points per second. Gaining diagnostic insights to guide technicians from telemetry data meant that Snap-on needed to be capable of analyzing and forecasting this data in real-time.

Actions Taken

Predii claims that their algorithm for making sense of telemetry data from Snap-on’s maintenance services was aimed at enabling the company to potentially perform analytics on telemetry data in real-time and forecast the data to aid current and predictive maintenance. At the time of writing, Predii did not provide any clarification on how the algorithm works or any examples of patterns in the telemetry data enabling predictive maintenance.

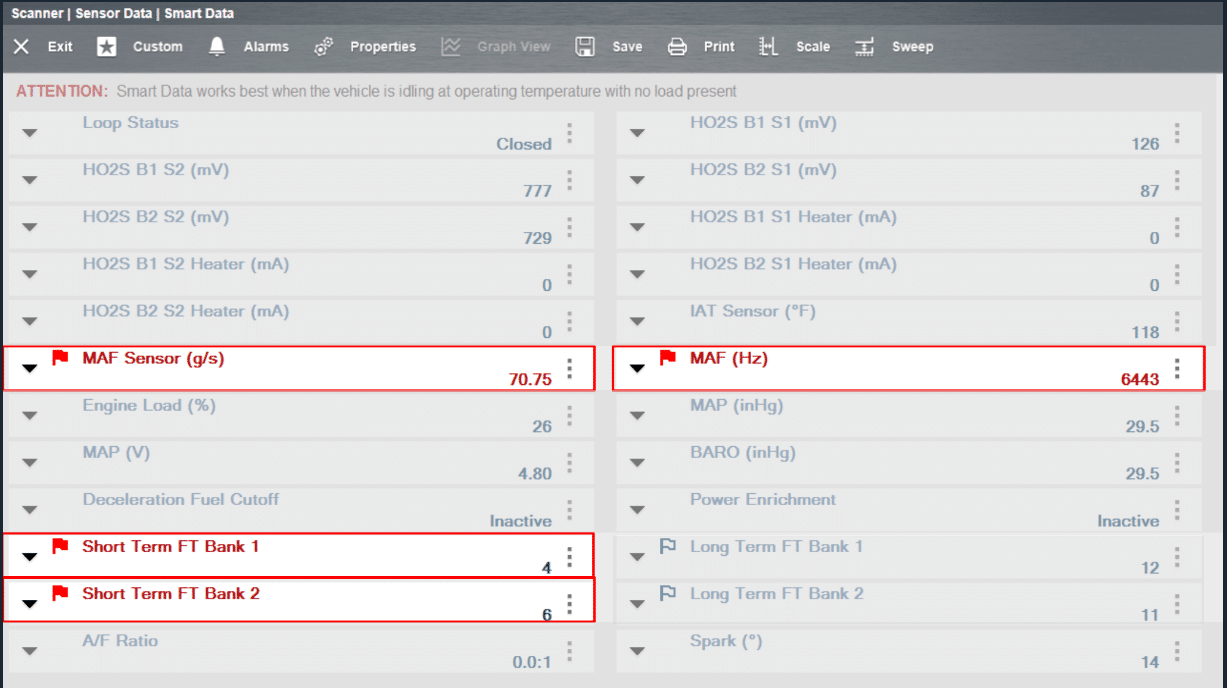

Given below is a screen-grab from Predii’s Repair Intelligence platform showing how vehicle telemetry data can be used by technicians. The company claims that their algorithm can identify potential anomalies in sensor data (as shown in red) based on past history and prompt actions for maintenance.

Problem 3: Repair Orders and Warranty Data

In the automotive industry, third-party vendor repair orders are commonplace and the invoice for such orders is created by multiple technicians working on the same vehicle independently. The human component in this operational data often translates to many challenges such as lack of language structure or grammatical errors. Snap-on wanted a way to find patterns in this unstructured repair order and warranty data to gain useful insights – for their technicians aimed at more efficient diagnostics.

According to Predii, gathering data from billions of such repair orders can potentially help maintenance technicians find pattern. For example, finding the most common type of repairs done on specific models of cars or trucks. According to Predii these types of patterns could potentially be gleaned from the repair order data.

Actions Taken

Predii worked with Snap-on to gather crowd-sourced data from repair orders that the company created, and built a customized ‘Unnatural Language Processing’ technology configured on this data. The company claims that their platform can analyze this unstructured data to potentially find diagnostic patterns and relationships.

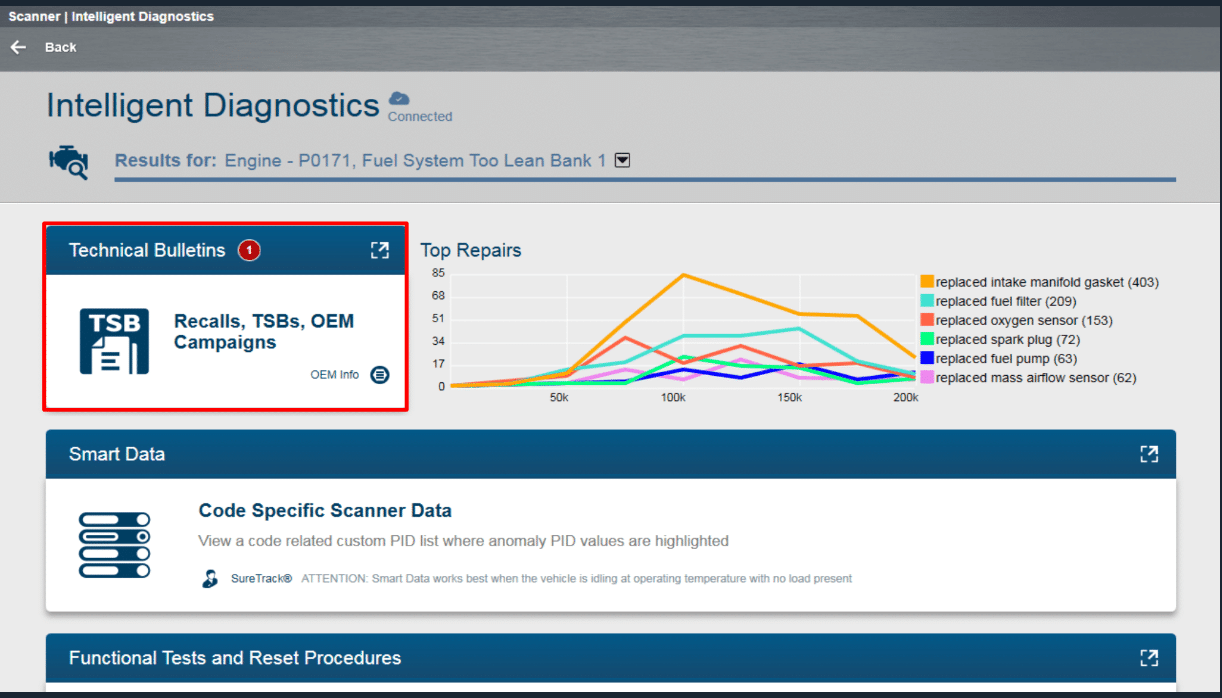

The image below shows a typical Intelligent Diagnostics screen from one of the products on Snap-on’s diagnostic tools catalog called Zeus.

Integration

According to Sierra Stanton from Predii, the Snap-on project involved collaboration between the data architects at Predii and the experienced technicians and vehicle maintenance experts who have acquired the nuanced knowledge of fixing vehicles. It was unclear though how many people from each team were involved or how long the collaboration was for.

She added that according to Predii, technicians in the automotive and industrial equipment environments are facing technology disruption and today it is very complex for any single technician’s experience. Predii claims, the Repair Intelligence platform uses service data to help field services personnel and technicians with guided repair.

Predii Repair Intelligence was configured using three sources of data:

- Sensor data

- Service order data

- OEM technical manuals

Sierra claims that the platform can find patterns and ‘learn’ from these three data sources to provide actionable insights to technicians. Sierra explained that the company used AI in Repair Intelligence in the following ways:

- Statistical machine learning techniques were used to make sense of the data — how to collect parameterized data from sensors, create baselines for readings, and identify the anomalies when something is about to break.

- In short, the historical telemetry data collected by sensors in the car was used to configure the ML platform which ‘learns’ to identify anomalies which are frequently associated with a specific type of repair service. This data is then forecast using a model to ‘predict’ potential failures in the future.

- Natural language processing techniques were used to make sense of service order data coming from repair shops.

- The service order data was also used to train the NLP platform to ‘extract and understand’ the repair order data. The next step involved a combination of unsupervised learning techniques and proprietary clustering techniques were used to form correlations and actionable insights like suggesting the most common sensor replacements performed for a particular model of truck.

Results

We were unable to get the degree of granularity that we would have preferred for this case study. Specific information about the impact of Predii at Snap-on wasn’t provided in depth. We received the following quote from Predii’s Sierra Stanton:

“One of the Snap-on products powered by Predii Repair Intelligence is a diagnostics tool, called Zeus (see figure below). Technicians using Zeus reported average savings of 30 minutes per job in diagnostic time”

Although we must add here that there was no information available on how long an average diagnostic session before the adoption of Zeus was. It was also unclear whether or not the impact of the time savings was affected by Snap-on’s internal strategies aimed at improving technician-time efficiency.

Transferable Lessons

Another quote provided by Sierra from Predii talks about some the ways that Snap-on potentially benefitted from the collaboration:

“There’s a trove of complaint/cause/correction data in service records, but it’s very difficult to mine gold from because it’s generally notes entered by hand. Reading one summary of a service order is easy. Reading and learning from millions of service orders in a few hours is an entirely different problem, and if you can solve it, you’re really winning.”

It must be noted that Snap-on had access to vast amounts of service records and sensor data which enabled them to use AI. For businesses that have access to a significant amount of customer/product relevant data, for example like maintenance data for machines or data from sensors in a factory, AI can potentially be a useful tool to both gain insights and monetize this data.

The transferrable lesson here is that AI technologies are capable of taking ‘reasonably’ unstructured (like the service repair orders, although they were written by technicians in many languages, contextually they were all specific to the domain of vehicle repair) or structured data (like OEM manuals or sensor data) and finding patterns which could potentially aid in saving time or reducing costs.

For example, documents like company wikis or organizational rule documents need to be managed by enterprise businesses for different locations. AI can today automatically tag and categorize that data and make information easily searchable eventually saving time for employees.