Supply chain management (SCM) is critical in almost every industry today – but it hasn’t received as much focus from AI startups and vendor companies compared to healthcare, finance, and retail. Businesses are showing increased interest in AI applications, from its benefits to fully leveraging the vast amounts of data collected by industrial logistics, warehousing and transportation systems.

With many of the world’s largest firms beginning to pay attention to what AI can do to improve the efficiency of their supply chains, we set out to answer the following questions for our business audience:

- What are the current applications of AI in supply chain management?

- Which applications are experimental, and which seem to have real traction and business value?

We’ve broken down this article into the following major application areas for AI in SCM. Within each section, we explore companies and use cases to examine their business value:

- Predictive Analytics for Demand Forecasting

- AI for Warehouse Management

- Chatbots in Procurement

While this article will cover a broad range of supply chain applications, readers with a specific interest in procurement can read our full article on cognitive procurement. Interested readers might gain an understanding of the AI applications in the related transportation industry may be interested in our previous article titled AI in Transportation – Current and Future Business-Use Applications.

Predictive Analytics for Demand Forecasting

LLamasoft

LLamasoft was founded in 2003 in Ann Arbor, Michigan and currently has over 500 employees. The company provides supply chain planning and design software for design, planning and visibility applications in supply chain.

Below is two-minute marketing video for Llamasoft’s offerings in the supply chain management:

The company claims its Demand Guru predictive demand modeling software, uses machine learning to identify hidden patterns (such as those in seasonal demand or correlations between external weather, demand and other influences) in historical demand data to help businesses identify ways to cut costs and increase operational efficiency across their supply chains.

For example:

- A business that sells furniture (like IKEA) might be able to use the Demand Guru platform and predict the everyday demand for different models showcased in one of their brick and mortar stores.

- Using historical sales data of for all the models which includes information like date and time of purchase, number of items purchased etc., machine learning models in Demand Guru might potentially ‘learn’ a particular trend in terms of seasonality, (such as an increase in sales during a particular holiday season). Additionally, the platform might be able to take into account weather data and news events to find correlations with sales patterns such as identifying that days accounted for more sales on weekdays.

An additional feature that comes with access to Demand Guru is the LLamasoft’s Data Cube, which the company claims to be a collection of curated weather and economic time-series datasets that can get the platform’s learning capability started on recognizing cause and effect relationships for predicting future demand. This might be access to data like temperatures and rainfall levels for a particular city in the US or data about mergers and acquisitions in a particular industry.

The 2-minute video below is a generic overview of what Llamasoft’s Demand Guru platform is capable of in terms of predicting demand in SCM:

In our preliminary research, we found several case-studies in which Llamasoft’s platform was used in SCM applications.

One such case-study we explore below details the application of Llamasoft’s platform to improving the efficiency of Schneider Electric’s global supply chain. Below we sum up the case study in terms of use specific purported use of artificial intelligence:

Challenge:

- Schneider wanted to reduce the costs involved in their existing supply chain flows for 240 manufacturing facilities around the world and 110 distribution centers and also analyze potential opportunities to assimilate new business units that they had just acquired

Actions Taken:

- Llamasoft was contracted by Schneider to build a supply chain predictive model that could automatically create the best routing options for Schneider’s enormous raw materials supply chain which includes circuit breakers that are small enough to fit on a store shelf to transformers that are the size of a large room.

- Enterprise supply chain data (such as transportation rates and policies, data regarding product shipping routes etc.) from a number of the new business units Schneider had recently acquired and the company’s existing supply chain data majorly resided in 27 legacy ERP systems.

- Data engineers at Schneider first built a data extraction tool that could collect the enterprise data from all the ERP systems, verify and ‘clean’ the data in order to be input to the Llamasoft platform.

Purported Results:

- Llamasoft claims that their customized model need around 2-4 hours to analyze 200,000 transportation policy data points, 130,000 flow and routing constraints, and more than 150 initial scenarios (Data provided by Schneider) and could identify $9.32 million (8 million Euros) in annual savings for Schneider which could potentially be obtained by altering product flow in the supply chain.

- For example, re-routing certain shipments directly from the manufacturing plants rather than through one of their distribution centers to save on material handling and inventory storage costs. (We must add here that from the case-study provided, there was no clear indication of how the 8 million Euros figure was arrived at or if any cost saving benefits were actually realized.)

Although Llamasoft’s Chief Science Officer, Nejat Karabakal has previously worked with IBM’s Supply Chain Optimization practice, we were unable to find anyone with robust academic or business experience with artificial intelligence on the company’s leadership team. This is not unusual for companies that didn’t begin with an AI offering, and instead developed AI applications long after having an existing core offering. This is indeed the case with LLamasoft.

Aera Technology (FusionOps)

Aera Technology (formerly FusionOps) was founded in 1999 in San Francisco and has approximately 153 employees today. The company offers predictive analytics software which the company claims uses machine learning (aided by domain experts) for applications in supply chain management. The company claims that it’s applications can help to automate planning and optimize existing supply chain flows for businesses.

For example:

- An automobile manufacturer in the US might have parts being manufacturing in many countries which then needs to be sent to distribution centers and dealers. Aera’s supply chain management platform might enable the manufacturer to easily keep track of the whole supply chain with products ranging from tiny screws to massive engines and get actionable insights from the platform aimed at reducing costs and improving efficiency.

- The company claims that its platform uses machine learning to find patterns in supply chain data (such as historical shipping records or stock keeping records at distribution centers) that might potentially help in providing insights enabling the manufacturer to deliver parts faster and reduce inventory storage levels.

This 3:15-minute video from the former Fusionops is a demo of its Insight platform (now part of the Aera Platform) showing how businesses might use the software’s actionable dashboards, reports, and metrics:

In a 2016 case study, Aera claims to have collaborated with Mahindra USA, (the North American tractor manufacturing arm of Indian automobile company Mahindra & Mahindra) to help reduce inventory stores and deliver parts to customers more quickly.

Challenge:

- Since 2011, Mahindra’s product portfolio had risen from 10 to around 55 and the number of dealerships grew 4 times at over 500. The company believed they needed a single source of actionable insights for improving supply chain efficiency at this scale.

Actions Taken:

- Aera’s platform was input with data from many internal teams in Mahindra including finance, operations, planning and business management. The company claims that it’s platform was able to use machine learning techniques and provide insights on reducing costs in the supply chain for Mahindra. For example the platform could potentially identify which international and domestic shipments could be combined to reduce costs.

Purported Results:

- Aera also claims that the integration of their platform helped Mahindra achieve a 35% reduction in their inventory storage Months of Sale (MoS – the number of months it might take to sell the current inventory at similar market conditions). Although no details on what other measures Mahindra might have taken simultaneously or the original MoS figures for Mahindra before the integration were unavailable.

Another instance of Aera’s platform being applied in supply chain demand planning is their collaboration of Merck, the pharmaceuticals company as reported by the Wall Street Journal.

Challenge:

- Merck wanted to automate some of its supply chain activity (decisions about allocating materials and distributing products) to make faster planning decisions.

Actions Taken:

- Merck deployed a suite of sensors coupled with machine learning predictive analytics software to improve its inventory and distribution efficiency.

- Merck engineers used the Aera Technology (formerly Fusionops) Insight machine learning capability of drawing on data from sensors on factory machines and their internal enterprise SAP software.

Purported Results:

- Merck also says a pilot run of the system resulted in 80 percent of the predicted test cases being more accurate than human experts at the same task. Further details on the scale or the parameters for the testing were not immediately unavailable.

AI for Warehouse Management

Automated guided vehicles (AGVs) have been operating in industrial environments since the 1950s, and until recently were largely incapable of autonomous navigation without physical path guiding mechanisms such as wires, tracks, or magnetic tapes.

With incremental improvements in AI and navigation technologies such as simultaneous localization and mapping, and machine vision, AGVs can enable automated material handling across traditional manufacturing boundaries by moving between buildings.

Today’s AGVs have the potential of being made relatively more autonomous by integrating them with data from existing warehouse management and control systems through a connecting software layer called warehouse execution systems (WES).

WES use AI to make existing logistical systems more efficient over time, and many of the top AGV players have made clear strategic decisions towards acquiring WES capabilities. We discuss some use-cases of some of the top AGV manufacturers using AI to offer WES services.

Dematic IQ (Former Reddwerks)

Dematic, founded in Grand Rapids, Michigan, Dematic in 1891 with over 4400 employees worldwide today is an American company that provides automation software for supply chain management applications.

Dematic acquired Reddwerks (an early entrant in the WES space), in 2015 to create its own WES based on Reddwerks’ Distribution Science (now under the Dematic Reddwerks brand). According to Dematic Reddwerks, its platform can aid warehouse management operations in identifying the most-efficient picking density for warehouse robots or in optimizing the order-release workflow.

In a case-study, Dematic worked with an American apparel retail manufacturer to support their retail store fulfillment (replacing items in stores) by using the Dematic IQ WES. According to Dematic, their WES was used to develop a distribution center for the to replenish products in 3,900 retail stores.

Challenge:

- The apparel retailer needed to change their store fulfillment operations for eight individual store brands into one distribution center which meant that the distribution center need to have a high density of storage and simultaneously ensure speedy product replenishment.

Actions Taken:

- The Dematic WES was used to optimize operational processes for the whole distribution center right from order receiving (from data in the clients ERP systems) to shipping and scheduling (with data from the WMS).

Purported Results:

- The company claims that Dematic retail store replenishment system helped the retailer to accommodate up to 600,000 pieces per day replenished in their stores which was about the required demand for all replenishment of all eight brands (including peak conditions). Dematic also claims that their system reduced processing costs and expanded storage capacity, although more detailed measurable results were not revealed by Dematic at the time of writing.

Below is a 4-minute video from Dematic giving an overview of some of the features of their WES platform, the Dematic IQ might be used:

We were unable to find anyone with robust academic of business experience with artificial intelligence on the Dematic leadership team.

Other notable market developments in the WES space have come from Vargo (developed its own WES), Honeywell Intelligrated, which acquired Knighted back in 2012, and Swisslog, which acquired Forte.

Swisslog

Swisslog is a 118-year-old company founded in Buchs, Switzerland with over 2300 employees today. The company is owned by German robot maker Kuka, which is a division of Chinese electronics business the Midea Group.

An emerging application area for AI seems to be in warehouse management systems (WMS) – commonly used by businesses to monitor and improve agility in the warehouse. AI-enhanced WMS learning has the potential of optimizing operations by spotting and detecting abnormalities.

Swisslog appears to be counting on a “learning warehouse“ to use intralogistics systems which can help improve efficiencies autonomously by learning the most-optimized workflows from data such as customer ordering behavior, a company’s machine use and its use of resources.

For example:

- Intelligent WMS software might help companies in the eCommerce and retail spaces to manage their inventory storage and transportation operations more efficiently by using predictive analytics.

- Swisslog says its learning warehouse might be capable of taking into account data from factors such as the eCommerce player’s marketing campaigns, weather conditions on a particular day or production logistics, to predict the likelihood of a customer order – For instance, if the eCommerce company ran a marketing campaign for a company selling umbrellas in the previous week. The platform might prompt the inventory managers during a future week (with rainy weather forecast) that their warehouses might have to increase their current stock of umbrellas to meet the demand.

- The company believes that in the future, their warehouse management platform might be closer to completely autonomous monitoring and might possibly be capable of prompting actions to better optimize operations for enterprises such as automatically. Although we found no evidence of case studies specific to AI applications in WMS to support this claim.

This 33-second Swisslog video shows what may be possible with the learning warehouse:

From our preliminary research we found evidence of Swisslog having several successful case-studies in logistics automation using automated guided vehicles (AGVs) and warehouse

management software although we could find no evidence of any successful implementation of their learning warehouse yet.

Chatbots in Procurement

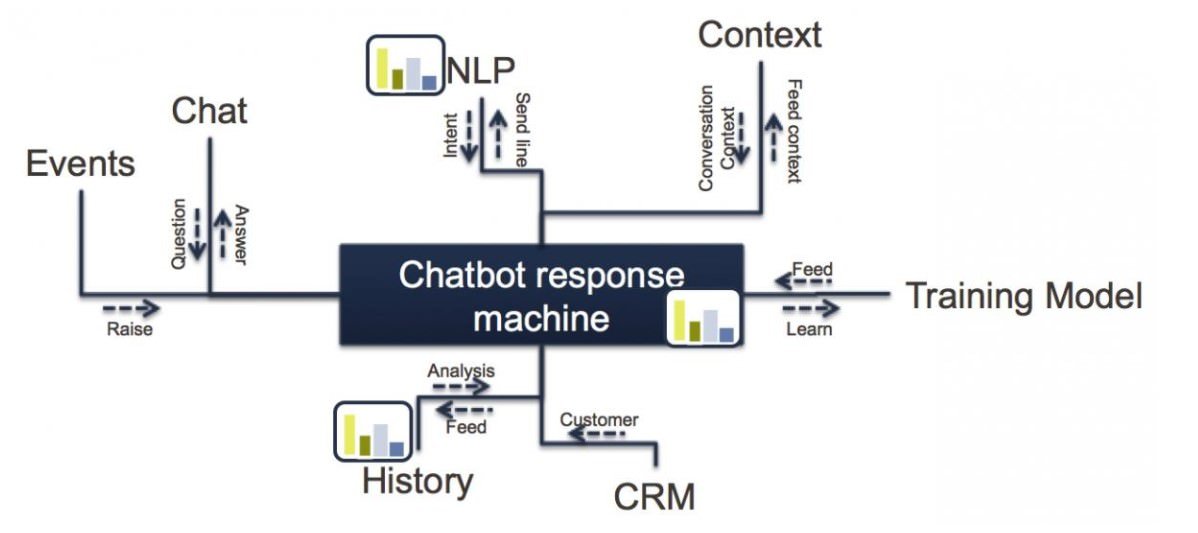

Conversational interfaces (chatbots) can potentially provide several benefits to businesses, including reduced cost of transactions and sales cycle time. This figure illustrates the different components that need to come together for chatbots to function:

Chyme by Univired

One example is Texas-based startup Univired, which has launched a chatbot, Chyme, which the company says can open conversational interfaces between human operators and sales/marketing automation services such as SAP’s SalesForce.

According to this case study from Univired, its chatbot was used in the beverages industry for procurement management. Beverages manufacturer used to require employees to call help-desk operators to obtain information about their procurement needs.

In most cases, that meant a forced waiting time to retrieve the information. The Chymebot solution, rolled out to employees and the suppliers, reportedly was able to provide answers to queries regarding order and shipment status, stock availability, stock prices, supplier status and contract details.

The 2-minute video below shows how SAP Sales Assistant has the potential to aid in automating procurement sales:

For all of those illustrated advances, there remain certain limitations to the successful integration of chatbots for procurement, including errors in chatbot integration that could snowball because of the nature of the systems and the obvious lack of a traditional human touch, all of it affecting customer relationships.

Businesses looking to leverage chatbots for procurement might be in a better position to make a decision by considering the following:

- Although it is relatively simple to do, integrating chatbots is not a guarantee of near human-like communication capabilities right off the bat; it is a long-term endeavor in which where existing data systems might need to be tweaked to ensure an accurate end result.

- Humans will still likely be irreplaceable in the next two to five years, although chatbots will probably help automate routine tasks and humans may be provided the skills to respond to more-complex queries.

Header image credit: G.O. Marine Services