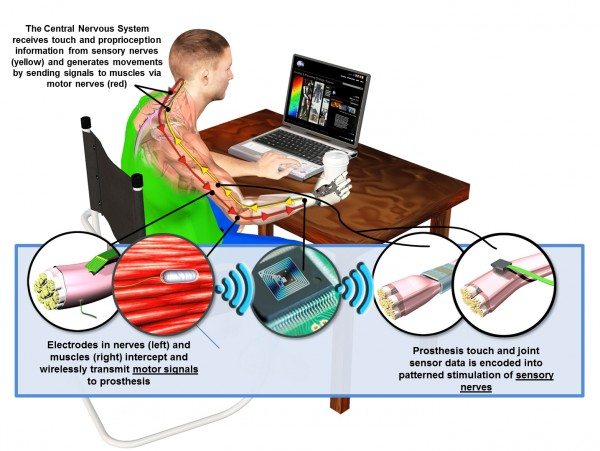

HAPTIX Helps Amputees

DARPA recently upgraded its Hand Proprioception and Touch Interfaces (HAPTIX) system in order to provide a range of sensations to amputees, empower them with intuitive control of advanced prosthetic devices and help reduce their incidence of phantom limb pain. HAPTIX aims to develop a system that will measure and decode signals produced by the muscles and peripheral nerves. The prosthetic limb will have built-in sensors to intercept the signals and will use them to provide feedback to the user though stimulation of sensory pathways in the peripheral nerves. As a result, the artificial limb will feel real and the user will have a sense of it being an integral part of their body.

FBI Facial Recognition Database

Concerns about personal privacy are being raised in relation to the FBI’s current plans to build a huge facial recognition database. By 2015, the Next Generation Identification (NGI) database will contain around 52 million images, more than double the amount it held in 2013. The database also contains 4.3 million images obtained for “non-criminal purposes,” though it is not clear where these images came from.

Although in the FBI’s fingerprint database, criminal and civilian data are kept completely separate, in the NGI database, criminal and non-criminal information will be stored together enabling a search to query the entire system. Even individuals who have not committed a crime may have their facial images searched through the new system.

Cow Milking Robot

Already popular in European countries, cow milking robots are now coming to a dairy farm near you. Gone are the days of the milk-hands who used to wash the cow’s udders, attach the milking machines and wait for the milking to finish. Now milking robots can take care of the whole process, and even know when the cow is ready to be milked.

The process is simple and effective. When it’s time for milking, the cow goes into a specially rigged stall where a laser scans a bar code on a collar around her neck. This enables the robot to know which cows are ready to be milked. Grain is automatically dropped into a trough in front the cow, so that she can eat while she is being milked. A robot arm with attached brushes cleans the udders, and lasers scan them, a milking nozzle is attached to each teatand milking begins. The robot stores all the information pertinent to each cow for future reference. If any problems arise with the cows, the robot can give the farmer a call.