Artificial intelligence is gaining traction in the agricultural industry and is steadily being integrated in robotics developed for this sector. As automated technologies penetrate the market, we aim to answer the important questions that business leaders are asking today:

- Which types of AI applications are currently available in the agricultural robotics market?

- How are agricultural companies using these technologies to stay ahead of the competition?

- What innovations have the potential to change the industry over the next decade?

In this article, we explore current and “near future” examples of agricultural robots (often called “agribots” or “ag robots”). Based on our research, most current ag robotics applications fit into the following sub-categories:

- Drones (Primarily Survailance)

- Precision Weed Control

- Crop Harvesting

- Planting and Seeding

Below we have selected 8 brief examples across these four sub-categories. Each provides a snapshot of how AI and robotics are converging within the agriculture industry. We’ve broken down the examples below into “current applications” (those that seem to be in use already), and “emerging applications” (those which show promise but seem farther from a robust business ROI).

Current Agribot Applications

Blue River Technology – Weed Control

Herbicide resistance has become a primary concern for stakeholders in the agricultural industry. The increasing use of herbicides has contributed to herbicide resistance which has been documented in 250 species of weeds. The Weed Science Society of America recently concluded that herbicide resistant weeds have been responsible for approximately $43 billion worth of financial losses for American farmers.

In response to the continued challenges that weeds are presenting to farmers, Blue River Technology has launched a weed spraying machine. The See & Spray robot has been marketed as a safer solution to herbicide resistance with claims that it significantly reduces the the crops’ exposure to chemicals.

The video below explores the robot’s functions in more detail:

In September 2017, noted agricultural company John Deere announced its acquisition of Blue River Technology for a reported $305 million.

Harvest CROO Robotics – Crop Harvesting

The U.S. Bureau of Labor Statistics has recently reported an anticipated loss of six percent of the agricultural workforce nationwide. In response to this trend, Harvest CROO Robotics has introduced a strawberry picking machine. In a 24-hour time span, the robot is reportedly capable of picking strawberries across eight acres of land.

With a reported 40 percent of nationwide farm costs going to wages and other labor costs, companies engaged in efforts to implement AI into agriculture are on the rise. The video below shows the Harvest CROO Robot in action:

The company claims that the machine’s general workload capacity is comparable to thirty human farm workers. Based on the U.S. 2016 median annual wage for one agricultural worker, 30 workers would amount to approximately $676,200 in annual costs. Harvest CROO does not publish the cost of its robot on its website. However, if we consider the price tag of a competing strawberry picking robot at $50,000, it is plausible that the Harvest CROO robot could provide cost savings.

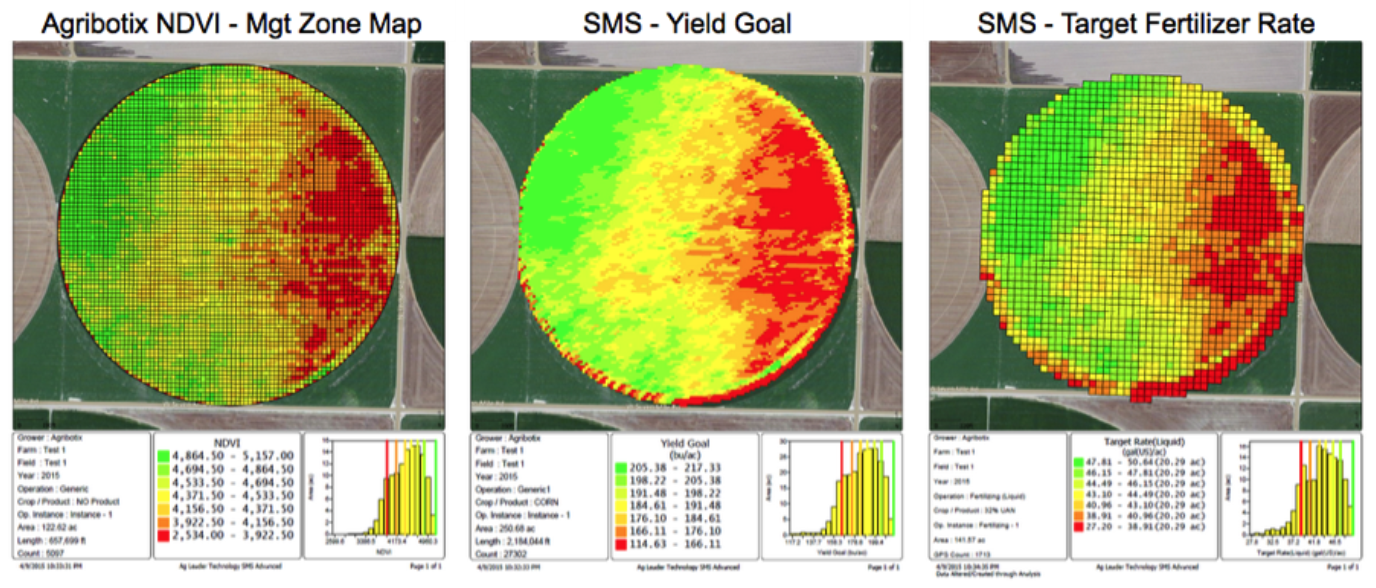

Agribotix – Drones

Colorado-based Agribotix reportedly takes agricultural data captured by drones and conducts analyses using cloud-based software to help clients increase crop yields and profits. According to the Agribotix website, the company claims that it has experience with more than 44 crops and its clientele base spans over 45 countries. The one minute video below provides a demonstration of a drone in action:

In one case study, Agribotix claims its technology helped a soybean grower prevent damage to its crops from weeds and avoided a 13 percent crop loss. The reported ROI amounted to $7,222.00, which included savings from crop loss avoidance and a precise herbicide application.

In May 2017, Agribotix announced its involvement in a partnership with The Climate Corporation to expand the Corporation’s suite of digital tools by integrating the ability to capture high resolution aerial images.

For example, as depicted in the image below from the company’s website, these aerial images provide a contrasting view of the terrain, highlighting which areas are healthy and which require attention. Theoretically, the information derived from these images would allow more efficient budgeting and planning of farming and harvesting procedures.

(We cover a few additional companies and use-cases for agricultural drones in our “Industrial Drone Applications” and “Machine Vision for Satellite Imagery” articles, respectively.)

Emerging and Future Applications

Vision Robotics – Planting and Seeding

Vision Robotics’ technology reportedly integrates algorithms with sensor technology to bring automation to lettuce farming and vineyards. Specifically, computer vision allows robots to generate 3D maps and models of areas of interest and then to complete various tasks within those parameters.

For example, “thinning” is a process in farming where seeds are adequately spaced apart during planting to allow for optimal crop growth. It can also be a time-consuming process. Vision Robotics’ automates the lettuce thinning and results are shown in the example image below:

Future initiatives appear to include the development of precision weed removal technology using herbacids and the company is actively seeking strategic partners. Vision Robotics has not published an anticipated timeline for this effort.

Crop Harvesting

In a 2017 survey conducted by the The Produce Marketing Association, apples and strawberries ranked 2nd and 4th place among the top 20 fruits and vegetable sold in the U.S.

Shibiya Seiki – Strawberry Harvesting

In 2013, Japanese company Shibiya Seiki made headlines with the announcement of a $50,000 robot reportedly capable of picking strawberries. Results from a research paper published by the company reported that the machine showed “potential for practical use” – and is clearly not in use with businesses today. It has been estimated that it takes a human 10 to 15 minutes to pick a quart of ripe strawberries, and – judging by the video below – this robot seems rather far from beating human performance in the near term:

The greenhouse setup for Shibiya Seiki’s research was customized, complete with a hanging strawberry garden setup with a particular density of fruit and a particular set of distances between plant beds. While the machine likely would be of little use in a normal (read: un-instrumented) berry farm setting, this application may help generate ideas about the super-efficient farm setups of the future (optimized for machine performance, not human performance).

The robot was developed in collaboration with Japan’s National Agriculture Food Research Organization (NARO). NARO’s current research efforts appear to include the development of fully-automated farms. It is unclear exactly when the organization expects to realize its ambitious effort.

Octinion – Strawberry Harvesting

R&D company Octinion’s strawberry harvesting robot is slated to officially debut in 2018. In comparison to Shibiya Seiki’s strawberry picking robot, Octinion emphasizes the ability of its robot to prevent damage to crops. The prototype was reportedly developed two years prior as demonstrated in the video below:

Like the Shibiya Seiki strawberry robot in the previous example, Octinion’s application seems to operate within a special farm layout with hanging fruit and neat rows at a specific picking level. We might imagine that fruit at various levels (or in different layouts) might be more challenging for the machine.

According to its website, Octinion claims its autonomous robot is developed with 3D computer vision which gives it the ability to only pick strawberries that it won’t bruise; this equates to picking an estimated 70 percent of all ripe strawberries.

The company reports that human labor results in ~16 kg of strawberries picked and sorted per hour (with about 56 strawberries per kg), equating to about one strawberry every four seconds. Comparatively, Octonion claims that its robot “has the capacity to pick one strawberry every three seconds.” Based on the video of the current robot (above), this speed seems rather exaggerated, and it seems obvious that many more iterations and improvements will be required before this machine reaches human skill in picking and sorting.

Octinion does not presently feature any case studies or real-world applications of it’s technologies on it’s website, nor is there evidence of current paying customers (though this information might be kept secret).

FF Robotics – Apple Harvesting

Historically, apple harvesting has been conducted manually. In 2012, an estimated 4.2 million apples were picked in the U.S. Israel-based FF Robotics has reportedly been working to perfect an automated apple-picking robot as demonstrated in the 2.5 minute video below:

While the company showcases instances of media coverage on its website, it is unclear what clients have invested in the technology to date.

Abundant Robotics – Apple Harvesting

California-based competitor Abundant Robotics is reportedly aiming to bring its commercial apple harvester to market by 2018. Co-founders Dan Steere and Curt Salisbury explain their vacuum-inspired technology in the video below:

In May 2017, Venture Capitalist firm GV (also known as Google Ventures) was reportedly a lead investor in a $10 million Series A investment in Abundant Robotics. However, it is difficult to grasp an idea of the experience of Abundant Robotics clients. The company’s website does not appear to provide client testimonials or case studies.

Concluding Thoughts on Agricultural Robots

Agricultural robots or agribots are changing the look, feel and pace of traditional farming practices. Crop harvesting is poised to significantly impact the agricultural sector over the next decade. Essentially, where consumer demand and labour requirements are the greatest, automation will prove most useful. For example, roughly 320,000 acres of apples are grown in the U.S. annually and each acre requires between 250 and 350 man-hours per acre.

However, it is important to keep in mind that there will be a learning curve as these technologies improve in their sensitivity and operation capacity. The industry appears to be inching towards large-scale efforts, so robot developers will need to keep this growing trend in mind.

Drone technology has reportedly demonstrated some promising results as in the case of Agribotix. In comparison to other robotic categories where ROI is scarce, the company’s openness to publish hard figures may reflect the sustainability of the this technology (we regularly publish reputable case studies of successful AI implementations in business, and we’ve found such published case studies to be relatively rare in the nascent world of agricultural robots).

Advances in drone research will be critical for maintaining safety considerations. Agriculture authorities and investors alike will require proof effectiveness and safety. We can anticipate more drone applications to attempt to come to market in the coming decade.

Barring adverse weather, drones seem to have the easiest chance of becoming a commonplace agricultural application because – unlike their grounded counterparts – they don’t need to navigate the unpredictable and messy world of sold and product.

Grounded machines require dexterity in interacting with plants safely, while drones can survey a domain and record image data without requiring the same kind of significant progress needed for other robotics applications (case in point: the dexterity and discernment needed to pick strawberries at human speed is a much harder problem than simply flying over crops). We suspect that drones will be among the first widely adopted agricultural robots in the near term.

While fully autonomous robots are a goal of many players in the agribot space, this should not overshadow the important role that humans will play in quality management. The evolving roles of robots and human laborers may potentially usher in new job roles that are more technical in nature.

AI agribots are poised to present new opportunities for the agricultural sector and we anticipate increased implementation across multiple areas of the industry.

Header image credit: Popular Mechanics